It’s wintertime, the season when a wastewater lagoon is most likely to short circuit due to the disparity between the influent wastewater temperature and the ambient lagoon temperature. In a previous article, Four Causes of Wastewater Lagoon Short Circuit, we defined what short circuiting is and what causes it. In this article, we’ll cover how to diagnose it and what to do about it.

How to diagnose lagoon short circuit

A short circuiting problem is usually discovered when testing reveals high levels of BOD or TSS in the effluent. There are several methods of determining if short circuiting is the cause of treatment insufficiency, such as:

- Temperature and DO reading: Measurements of temperature and DO levels taken vertically every 6” from the top of the lagoon to the bottom will indicate whether thermal or biological stratification exists. If there is stratification, there is likely short circuiting. Effluent warmer than the overall lagoon temperature is also an indicator of a short circuit.

- Effluent testing: A TSS:BOD5 ratio of 1—the same ratio as untreated wastewater—in the effluent indicates short circuiting. Normal treatment performance for lagoons is a TSS:BOD5 ratio of 1.5.

- Microscopic examination: Raw sewage and sludge particles in the effluent indicate a short circuit.

- Dye testing: If a short circuit is suspected, dye testing can confirm it and demonstrate where it is occurring. A nontoxic fluorometric tracer dye is introduced into the lagoon; twice-daily testing with a fluorometer tracks its progress, allowing the operator to calculate actual retention time and flow patterns.

How to prevent wastewater short circuit

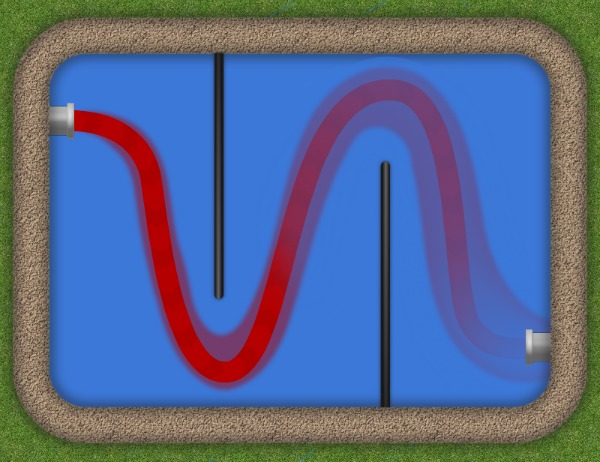

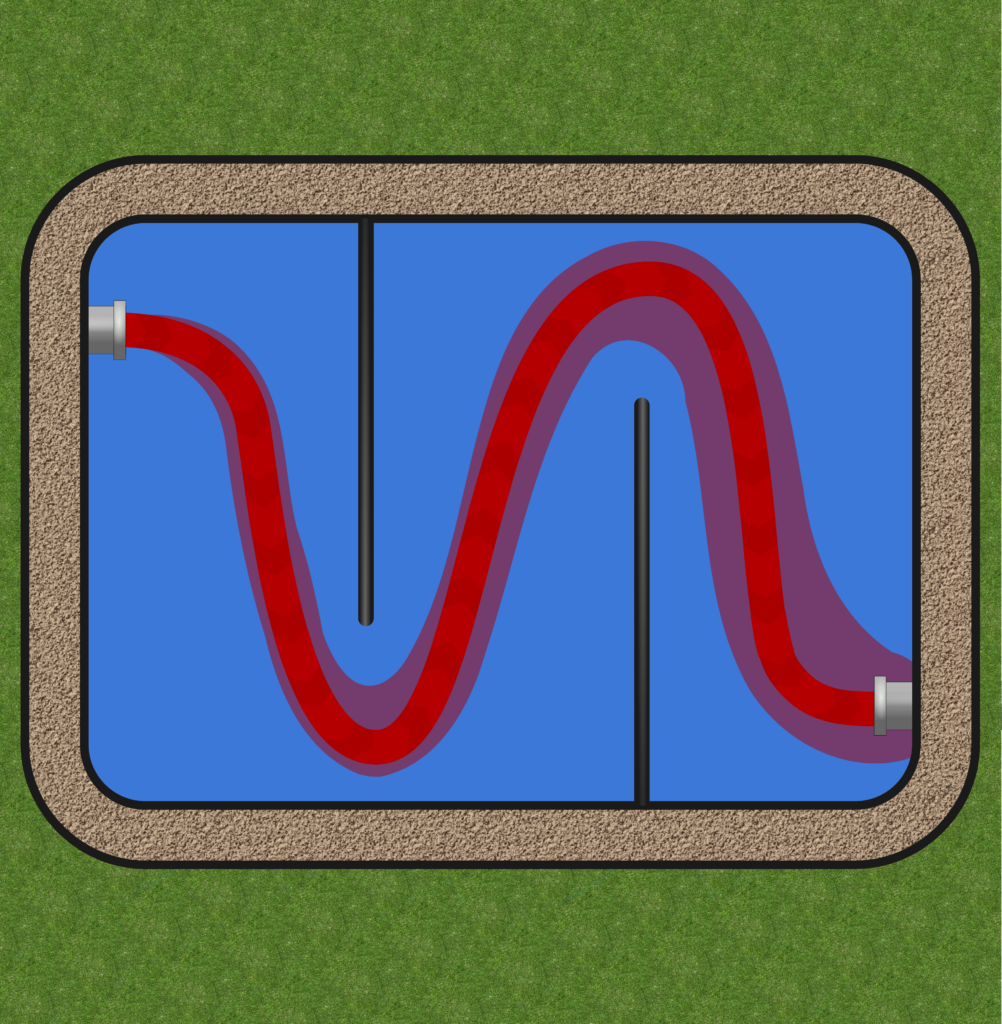

Evenly spaced baffles 70% of the width of the lagoon can prevent short circuiting.

- Improve lagoon design: In his Wastewater Lagoon Troubleshooting: An Operators Guide, Steve Harris recommends running influent through a manifold to distribute the load more evenly. Influent and effluent pipes may need to be repositioned as well. The addition of baffles can prevent a short circuit by manipulating flow patterns to improve retention time and promote the settling of solids. Studies have shown that long, evenly spaced baffles 70% of the width of the lagoon provide the greatest efficiency; however, mathematical modeling may be required to determine the optimal size, number, and placement of baffles for a particular installation.

- Correct infiltration and inflow: Lagoon I&I needs to be corrected at the source, by sleuthing out and correcting breaches in the system. For more details, see Lagoon Infiltration and Inflow: Problems and Solutions.

- Deal with sludge: Excessive sludge buildup can be corrected with dredging and removal, bioaugmentation, or improved mixing and aeration. See Wastewater Sludge Treatment or Removal? for a closer look at options.

- Prevent stratification: Mixing and aeration throughout the water column prevent sludge buildup and stratification that can lead to short circuiting.

Ares Aeration® prevents short circuiting

The mixing and aeration capabilities of the Ares aeration unit disrupt the stratification that leads to short circuiting and insufficient treatment. Each Ares aerator incorporates a coarse bubble static tube that releases large bubbles, creating a draft effect that pulls water and liquefied organic matter up from the basin floor. This produces wastewater mixing by highly agitating the water column, thoroughly churning and circulating the entire wastewater basin. This time lapse video shows how efficiently Triplepoint’s aeration distributes dye throughout the entire volume of the lagoon:

The robust mixing capability prevents stratification that can lead to lagoon short circuit.

Fine bubble diffusers surround the static tube, maximizing oxygen transfer efficiency (OTE) while minimizing energy consumption. Enhanced by the mixing effect of the coarse bubble, this combination provides the ideal environment for biological treatment. Due to the Ares’ industry-leading high airflow and mixing capabilities, the total number of units necessary to treat a facility is minimized. As a result, costs from installation materials and labor and long-term maintenance are all greatly decreased.

For more information, download our Ares Aeration Literature or contact us and we will be happy to help you with your lagoon aeration project.