One of the biggest challenges for all types of wastewater systems, including lagoons, is infiltration and inflow. In this short article, we’ll define Lagoon Infiltration and Inflow, commonly abbreviated as “I&I,” explore the causes, and discuss what can be done to mitigate it.

What is Lagoon Infiltration & Inflow?

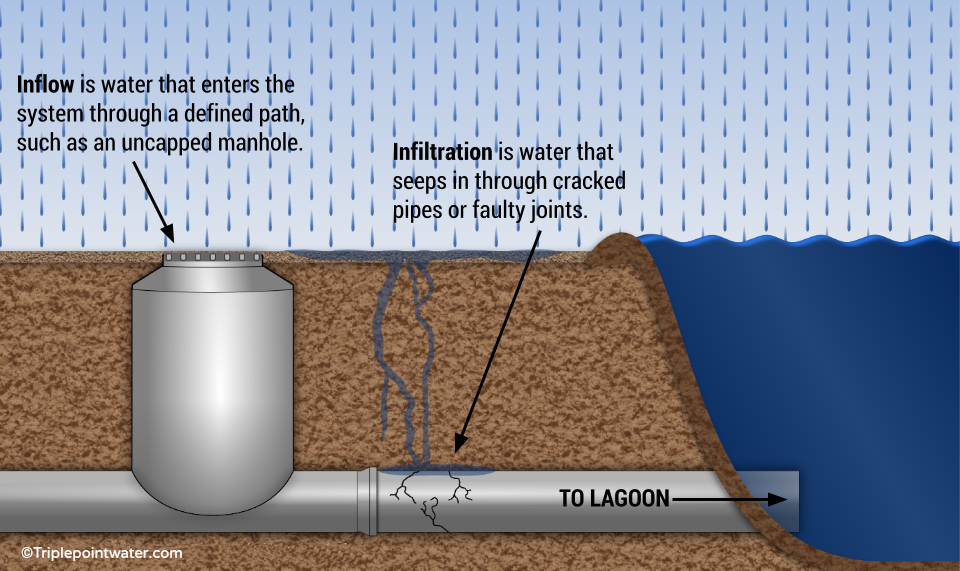

Lagoon I&I encompasses all water that finds its way into the wastewater system through “unofficial” channels. Infiltration describes water that enters the sanitary system through flaws in the infrastructure, such as cracked pipes or failed joints. Stormwater can seep down through the ground and find its way through cracks into the sewer pipe; or, when the water table is high, groundwater can seep in from below. Similarly, during periods of dry weather, sewage can exfiltrate from the pipe and contaminate the groundwater. Unaddressed infiltration problems will get worse as the infrastructure continues to deteriorate. Hydrogen sulfide (H2S) from wastewater sitting in pipes can also cause structural degradation over time and lead to cracks that contribute to infiltration.

Inflow is water that enters the system through a defined route, such as through unsealed cleanouts and manhole covers, catch basins, abandoned wells, and sump pumps, on both public and private property.

I&I is typically clean water, but once it enters the system and is contaminated with wastewater, the entire stream must be treated before discharge, requiring additional treatment capacity and expense. When there are major rainfall events, I&I can create influent of up to five to ten times the system’s design capacity, so it’s easy to see how I&I can overwhelm the treatment system.

Although infiltration and inflow enter the system through different channels, it all ends up in the same place: in the lagoon, where it becomes a headache for the lagoon operator.

Problems Lagoon I&I Can Cause

Lagoon infiltration and inflow cause many of the same issues as organic overloading, namely low DO, undertreatment, and discharge violations. Lagoon I&I:

- Overwhelms capacity: During a major rainfall event, a wastewater collection system with a major I&I problem could receive an influent surge of 5–10 times the design average, exceeding the capacity of the lagoon and causing overflow. A lagoon with seasonal discharge might experience continuous discharge and spillage, leading to violation of permit and fines.

- Lowers DO: Sufficient Dissolved Oxygen (DO) levels are critical to lagoon wastewater treatment. A lagoon with low DO—less than 2mg/L—lacks sufficient oxygen for the digesting organisms to do their work, leaving wastewater undertreated.

- Reduces retention time: With increased flow coming into the lagoon, retention time is reduced, thereby leaving less time to treat the wastewater. This can lead to violations in the discharge permit due to insufficient treatment.

- Causes short-circuiting: If the influent water temperature is warmer than the water in the lagoon, the lagoon is likely to short-circuit. Taking the path of least resistance, influent rides along the warmer top layer of the water, and flows, virtually untreated, out with the effluent.

- Is expensive: According to Ace Pipe Cleaning, which provides inspection and sealing services to correct sewer infiltration, if just 20 percent of the joints in a 300-foot section of 8″ pipe are leaking one gallon per minute, over 10 million gallons of water will infiltrate the system. If, conservatively, it costs $2 per thousand gallons to treat wastewater, that’s over $21,000 in additional costs annually, from just one 300-foot section of pipe.

How to Locate Lagoon I&I Sources

Generally, most I&I is inflow, which is usually easier and less expensive to detect. Inflow entry points can be located by inspecting catch basins, drains, and manholes. Infiltration problems, being underground, can be difficult and costly to locate; finding them requires some detective work and special equipment. Some common methods of evaluating the condition of the infrastructure to pinpoint I&I sources are:

Smoke testing: Pressurized smoke is blown through the sanitary system from a manhole. Places where smoke emerges indicate uncapped drains or breaches in the pipe. For a detailed look, see the Water and Wastes Digest article, Smoking Out Sewer Leaks: An Overview of Smoke Testing, an Important Part of I&I Studies.

Dye testing: A colorful, nontoxic dye is introduced into potential inflow or infiltration points, such as drains and ditches, and the sanitary sewer is monitored with a camera to see if the dye appears.

Video inspection: A remote controlled closed-circuit video camera is sent through the mains to provide images of the condition of the pipes.

How to Fix Lagoon I&I

Inflow is mitigated by capping or sealing open access points like manholes, roof drains, and catch basins. To correct infiltration, broken pipes must be located and repaired. While this process is expensive, it will rapidly pay for itself in reduced treatment costs. Ace Pipe Cleaning calculates the investment in repair will be recouped in less than two months, based on the example of a 300-foot section of pipe allowing infiltration of 10 million gallons per year. At an industry average of $8–12 per foot for pipe sealing with chemical grouting, an investment of approximately $3,000 will save over $18,000 in excess treatment costs the first year alone.

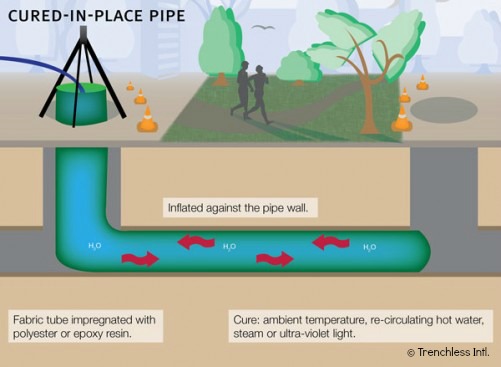

Once a cracked pipe is located, it can be sealed from above ground. The process is known as trenchless rehabilitation, and includes CIPP, or cured-in-place pipe; sliplining; and chemical grouting, among other technologies. For an in-depth look at CIPP, see the EPA’s A Retrospective Evaluation of Cured-In-Place Pipe (CIPP) Used in Municipal Gravity Sewers, which includes an overview of pipe rehab technologies and case studies.

Help Is Available

Many rural water associations offer assistance in diagnosing I&I; for example, the Missouri Rural Water Association provides on-site smoke testing assistance to its members. The South Dakota Rural Water Association provides smoke testing and video sewer inspection and invites its members to attend the sessions as part of its ongoing operator training. Check with your local rural water association to see if they offer similar programs.

In the meantime, the aerating and mixing capabilities of Ares Aeration® will help mitigate effluent problems caused by lagoon I&I by increasing DO and preventing short-circuiting. However, it is, at best, a stop-gap measure. I&I problems must be corrected at the source, and the sooner the better; as infrastructure continues to deteriorate, I&I will only get worse.

Lagoon I&I is one of the more difficult challenges an operator can face. In addition to lagoon-site challenges, the operator is also responsible for the water system as a whole because problems elsewhere in the pipe eventually end up in the lagoon.