Fruit processing wastewater is challenging to treat due to the seasonal nature of the industry and widely variable flows and loadings, with influent BOD levels much higher than typical municipal influent. Treated effluent, instead of being discharged, can be stored and used for crop irrigation, reducing the cost of external water sources.

This video case study shows how Triplepoint’s aeration allows an industrial fruit processor to store their wastewater odor-free for beneficial reuse in irrigation.

Case Study: Fruit Processing Wastewater Lagoon

Shelby, a town of about 2,000 residents northwest of Grand Rapids, is home to Michigan’s largest privately-owned fruit processor: Peterson Farms. Their processing complex markets over 150 million pounds of frozen fruits and 7 million gallons of juice products annually.

Peterson Farms wanted to pre-treat and land apply their wastewater, which required a lagoon cell both for treatment and storage. As a result, they decided to install Triplepoint’s aeration and mixing units in the holding cell to avoid solids settling rapidly, which would lead to sludge buildup and reduced capacity. These solids would also potentially clog irrigation equipment and lead to offensive odors.

Challenges of Fruit Processing Wastewater

Vegetable and fruit processing creates large amounts of wastewater, half of which is organic liquids like juices, and half of which is sanitizing washwater, which may contain chemicals. In addition, fruit and vegetable processing produces solids like peels, seeds, and stems, and may also include dirt from raw produce, all of which contribute to high suspended solids (TSS).

Moreover, fruit and vegetable processing is seasonal, with wide variations in flows and loadings. Wastewater treatment needs to be responsive to these changing needs and offer the flexibility to cope with production surges without wasting money on excess capacity.

Triplepoint's Lagoon Aeration Improves Treatment, Prevents Odor

Peterson Farms has an average wastewater flow of over 1.5 million gallons a day and a high strength influent BOD concentration of 927 mg/L, which far exceeds a typical municipal BOD of 100–400 mg/L. After initial treatment in an aerated basin, wastewater for beneficial reuse is held in a lagoon with a capacity of over 10 million gallons and a variable depth of up to 18 feet.

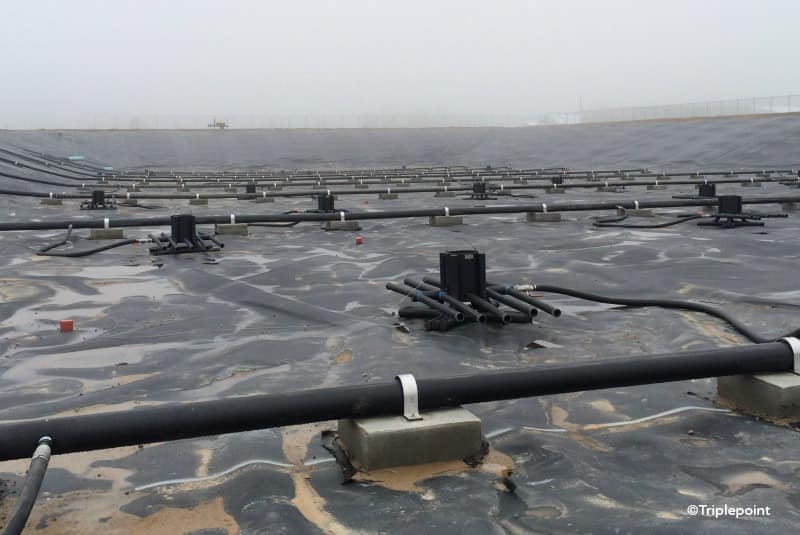

Forty-six of Triplepoint’s aerators on submerged laterals were installed at the bottom of the lagoon. Air is supplied by two 125 hp blowers; a variable frequency drive (VFD) in the control panel allows the operator to throttle up or down to cope with the changing treatment demands of an irregular production schedule without wasting energy.

The aeration units create a partial-mix environment that suspends organic solids in the lagoon where they can oxidize while allowing nonvolatile solids like dirt to settle out.

About Triplepoint's Lagoon Aeration

Triplepoint’s aerators, which feature patented Double Bubble Technology™, combine the mixing capabilities of coarse bubbles with the superior oxygenation of fine bubbles in a modular, portable unit. Our diffusers provide:

- Robust mixing—Coarse bubbles are released at the bottom of the static tube, creating a draft that pulls water and liquefied organic matter up from the floor, thoroughly churning and circulating the entire water column to keep solids in suspension and prevent sludge accumulation.

- Efficient aeration—Fine bubble diffusers surround the static tube maximize oxygen transfer efficiency while minimizing energy consumption.

- Easy installation—Self-weighted and portable, aerators are quickly installed from the surface with no system downtime.

- Low maintenance—There are no submerged moving parts to clog or malfunction. The anti-fouling design, with self-checked diffusers and self-cleaning EPDM membranes, means maintenance is kept to a minimum.

- Energy efficiency—Our aerators are 30–50% more energy efficient than surface aerators, reducing energy demands and expense.

Prevent Fruit Processing Wastewater Odors

Although Peterson Farms was not relying on the aerated holding cell for treatment, the efficient aeration and robust mixing have increased overall BOD removal, reduced sludge, and prevented odors.

Peterson Farms is proudly committed to sustainability, and Triplepoint’s aeration helps them along that path with energy efficiency, flexibility, and the ability to reuse their wastewater for irrigation.

For more information, download our Aeration Literature or contact us and we will be happy to help you with your food industry lagoon aeration project.