Is your wastewater lagoon ready for winter?

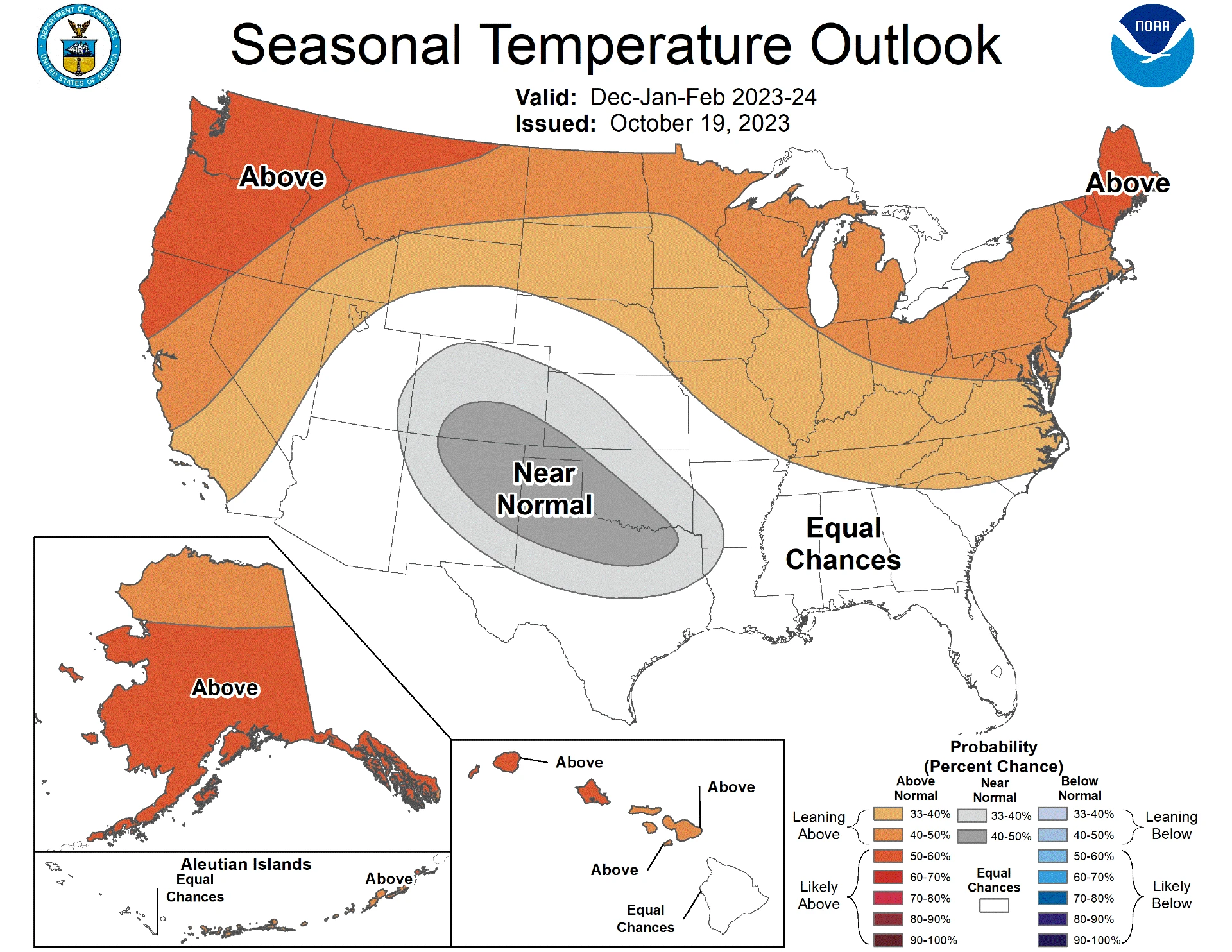

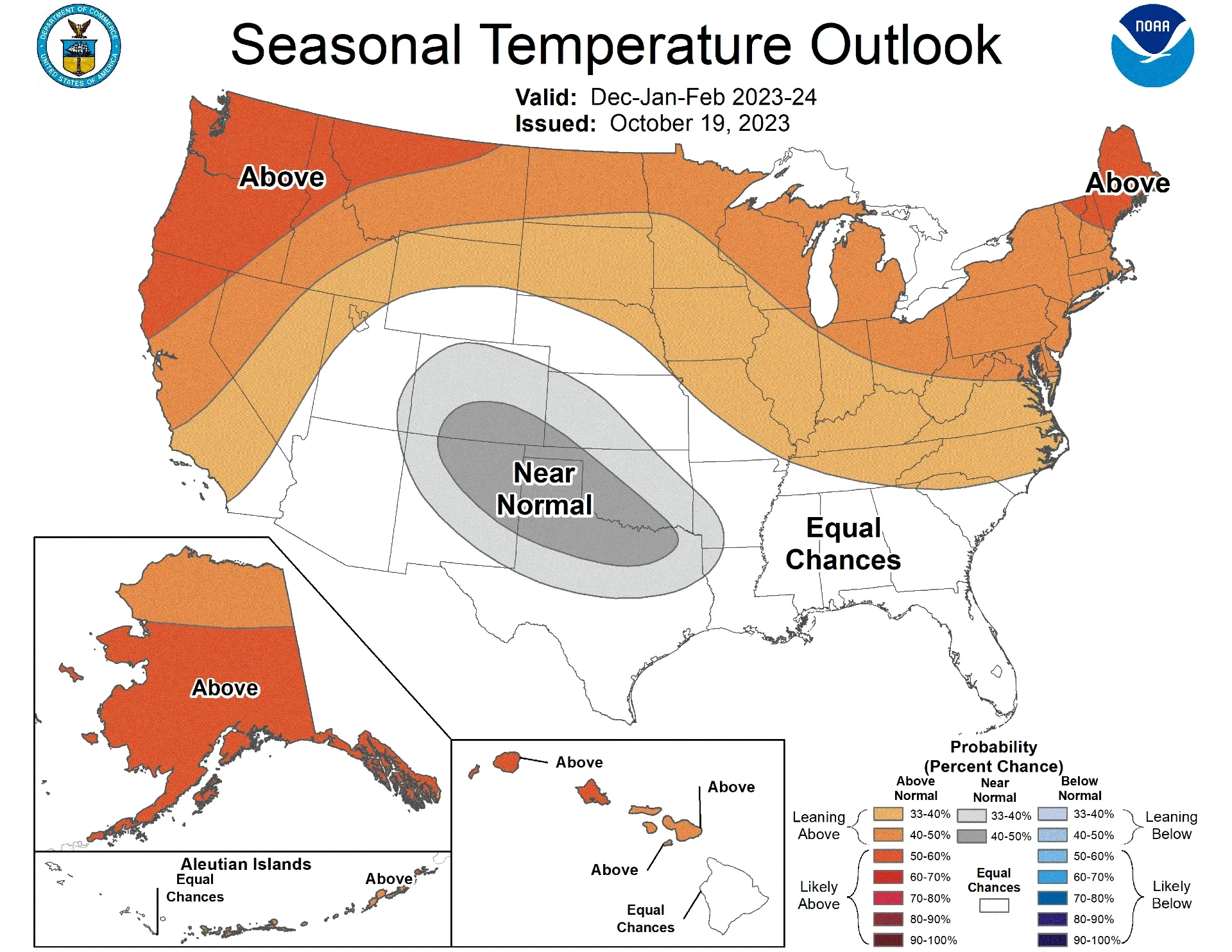

The National Oceanic and Atmospheric Administration (NOAA) is predicting an El Niño winter in the United States this year, with warmer-than-average temperatures in the northern half of the U.S. and equal chances for warmer, cooler, or average temperatures in the south. With the winter season upon us, it’s a good time to examine what happens to a wastewater lagoon in winter and highlight ways to optimize cold weather wastewater lagoon operations.

In this brief article, we’ll look at the effect of temperature on a wastewater lagoon, what happens in your lagoon when the weather gets cold, and how you can ensure the best possible treatment levels despite the weather.

The impact of temperature on wastewater lagoon operations

Water temperature affects virtually every aspect of wastewater lagoon performance. As lagoon expert Steve Harris states in his operators’ guide, Wastewater Lagoon Troubleshooting, “Water temperature is a reliable predictor of water quality and can aid the operator in preparing for changes in pond performance.”

Falling temperatures have predictable effects on a wastewater lagoon operations. A freezing water temperature:

- May damage structures and equipment: Icing over of liners, baffles, air and power lines, aerators and the like can cause significant damage. In addition, aeration equipment, especially surface aerators, can freeze and malfunction, leaving the lagoon without aeration and more prone to ice over.

- Causes destratification: As temperatures drop in winter, the surface layer of the lagoon cools and becomes denser. The heavier water sinks, displacing the warmer water at the bottom of the lagoon. This process, known as densimetric mixing, causes the lagoon to destratify and distributes cold water throughout the entire lagoon.

- Encourages short-circuiting: Warmer influent, if not properly mixed or if subject to wind, may short-circuit, or ride warmer thermoclines out with the effluent without being fully treated, especially if the lagoon surface is iced over.

- Builds up BOD: Every 10 degree reduction in temperature reduces microbial activity by 50%. Bacteria and algae slow down their digestive processes in colder temperatures, allowing BOD to accumulate.

- Reduces DO: Ice covering the lagoon surface prevents surface adsorption of oxygen from the atmosphere.

- Causes sludge buildup: Without sufficient DO, anaerobic conditions prevail and solids settle at the bottom of lagoon. Also, the bacteria slow down in colder temperatures, leading to lower sludge digestion.

- Stops nitrification: Nitrifying bacteria prefer warm water, with an optimal range of 82–97° F. Lagoon ammonia removal virtually stops at the freezing point of 32° F. For more information on cold weather nitrification, see our article 6 Tips to Remove Ammonia from Wastewater Lagoons and download our NitrOx Lagoon Ammonia Removal brochure.

- Affects phosphorus removal: Like nitrogen, phosphorus removal is temperature sensitive: According to Nutrient Removal in a Cold-Region Wastewater Stabilization Pond: Importance of Ammonia Volatilization, Journal of Environmental Engineering (April 2006), nearly 50 percent of influent phosphorus was lost from the water column during the summer-fall treatment period, but only about 35 percent was removed during the winter-spring period. Continuous discharge lagoons with effluent phosphorus limits may need to add a tertiary filtration system.

- Promotes conditions for spring lagoon turnover: The ice cover seals in the gaseous byproducts of anaerobic digestion. In spring, warming water instigates a burst of biological activity as dissolved oxygen levels improve and the microbes feast on the backlog of BOD. Gases entrained in the sludge cause it to rise to the surface. As the ice cover melts, the built-up gases and sludge are released all at once—along with terrible sulfurous odors that can linger for over a week—making your neighbors very unhappy. For more information see our article on Lagoon Turnover.

Optimizing wastewater lagoon operations in winter

The best defense against cold weather lagoon challenges is to be prepared:

- Protect equipment: Be sure surfaces around the lagoon are clear of road gravel, which can damage the lagoon liner with the freeze-thaw cycle. Cover or store unnecessary equipment.

- Check and maintain outdoor equipment: If you have any motors sitting outside all winter long, including blowers or surface aerators, change the oil and check any belts for wear and tear. By properly maintaining these motors now you can reduce the risk that they will fail during the cold winter months when it will be harder to access them.

- Prevent short-circuiting and spring lagoon turnover: Thorough mixing of the entire water column will ward off thermal stratification. Without thermoclines, warmer influent will incorporate into the overall mix and not flow out untreated. In addition, with a homogeneous water temperature and environment, no spring lagoon turnover can occur.

- Increase DO to reduce BOD and sludge buildup: Microbial populations require dissolved oxygen to digest BOD and keep it from building up as sludge. Provide sufficient oxygenation by adding aeration.

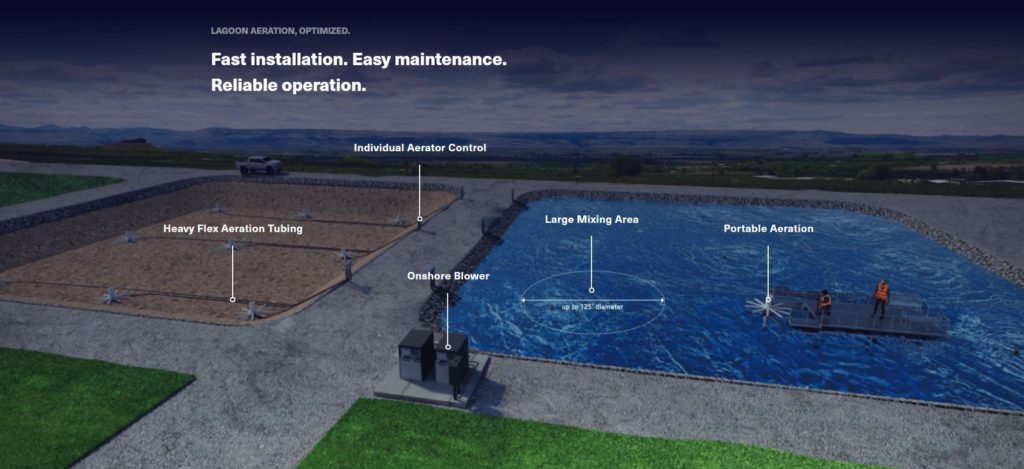

Ares Aeration® is reliable year round

The Ares Lagoon Aeration System optimizes lagoon performance year round, combining the mixing advantages of lagoon coarse bubble diffusers to keep solids in suspension with the efficiency of fine bubble diffusers for superior oxygenation in a high flexibility, low maintenance, portable unit. Each self-weighted unit is connected to an on-shore air supply via flexible weighted tubing. Because there are no mechanical parts submerged in the water, Ares aerators will not malfunction due to freezing, ensuring reliable performance no matter the weather.

For more information, download our Ares Aeration brochure or request a quote and we’ll be happy to help you with your lagoon aeration project.

Download the Ares Aeration brochure.