It’s spring! The snow is melting, the birds are chirping, and all the solids that settled to the bottom of the wastewater lagoon over the winter are getting dislodged, releasing sludge and gases that create spring lagoon odors.

For many municipalities, the spring and fall lagoon turnovers with their accompanying foul odors are just signs of the season. Some towns have chosen to live with the semiannual turnover and odor complaints, as the alternative—replacing an otherwise effective lagoon system with a multimillion-dollar mechanical plant—stinks even worse.

One possible solution that may seem attractive is the lagoon circulator. Often solar- or wind-powered, these devices promise to destratify, improve circulation and mixing, add dissolved oxygen, mitigate algal growth, and prevent odors. But do they work? In this article, we’ll explain what causes lagoon turnover, then take a look at lagoon circulators and evaluate their efficacy in preventing spring lagoon odors.

What causes lagoon turnover?

In the spring, increased sunlight warms the top layer of the lagoon, melting the surface ice and allowing sunlight to penetrate, creating convection currents. Gradually, with the sun’s warmth and wind, the entire lagoon reaches a uniform temperature and circulation increases.

This increased circulation disturbs the accumulated sludge and solids that have been lurking at the bottom of the lagoon. They get pushed to the surface, releasing hydrogen sulfide (H2S), the stinky gas that is generated by anaerobic digestion. The dislodging of the settled sludge and solids also results in benthal feedback or benthal release, which is when nutrients like nitrogen and inorganic materials like metals that have been trapped in the sludge get released back into the lagoon. Benthal feedback can cause ammonia levels in the lagoon to be higher than in the influent.

This increased circulation disturbs the accumulated sludge and solids that have been lurking at the bottom of the lagoon. They get pushed to the surface, releasing hydrogen sulfide (H2S), the stinky gas that is generated by anaerobic digestion. The dislodging of the settled sludge and solids also results in benthal feedback or benthal release, which is when nutrients like nitrogen and inorganic materials like metals that have been trapped in the sludge get released back into the lagoon. Benthal feedback can cause ammonia levels in the lagoon to be higher than in the influent.

Triplepoint’s NitrOx® removes lagoon ammonia in any weather

A facultative lagoon will develop over its surface an odor cap—an aerobic layer of water with a dissolved oxygen (DO) content of 2 mg/L—that acts as a barrier to prevent the release of large amounts of hydrogen sulfide and the associated odors. As the sulfide bubbles created by anaerobic digestion emerge through the highly oxygenated cap layer, they are oxidized to sulfate.

The warmer temperatures also wake up the bacteria that have been dormant, which set to work consuming the biological oxygen demand (BOD) that’s accumulated over the winter. The problem is, BOD-eating bacteria need dissolved oxygen to work, and there just isn’t enough. In the spring, a wastewater lagoon can need as much as triple the usual amount of DO—as much as 5–6 lbs. of O2 per pound of influent BOD—to handle the increased load. Once the bacteria chow through the DO in the odor cap, there’s nothing preventing all the sulfide gases from being released and—voila—spring lagoon odors.

What are lagoon circulators?

There are several types of lagoon circulators, which can be solar, wind, or grid powered, that generally operate along the same principle: The circulator is installed at the surface; a subsurface impeller tube pulls low DO water from the lower depths, pulls it up near the surface where the DO levels are higher, and recirculates it radially, often over a long distance. Although lagoon circulators are sometimes branded as mixers, their function is not to mix: They do their work within the natural stratification of the water in the facultative zone between the surface and the settled solids at the bottom of the lagoon.

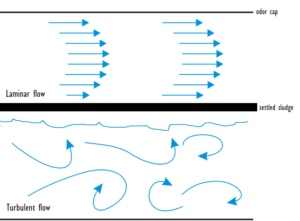

Circulators provide laminal or near-laminal flow, which moves water without disturbing the stratification that forms the anaerobic digestion area at the bottom of the lagoon and the odor cap on the surface.

Circulators provide laminal or near-laminal flow, which moves water without disturbing the stratification that forms the anaerobic digestion area at the bottom of the lagoon and the odor cap on the surface.

Facultative lagoons rely on wind to provide interplay between the aerobic and anaerobic layers of the lagoon. The lagoon circulator enhances this effect, to improve oxygen transfer and disrupt the formation of algae mats.

How well do lagoon circulators work?

While any additional movement in a lagoon or waterbody will assist in improving DO levels and prevent algae matting, circulators are less successful at treating odors and sludge because they don’t provide the turbulent mixing that keeps solids in suspension where they can be digested, and they don’t prevent thermal stratification.

A Water Quality Impact Evaluation performed by the UNC Charlotte Environmental Assistance Office determined that solar circulators installed into a freshwater lake for the purpose of decreasing thermal and dissolved oxygen stratification yielded “undetectable improvements” because the units did not provide sufficient mixing to break down the thermal layers.

Solar circulators installed in a bay in Madison, WI, were removed after it was determined they provided no benefit, and, further, could actually exacerbate the growth of blue-green algae (cyanobacteria) by stirring up the settled nutrients in the water.

A study of dairy wastewater published in the Journal of Applied Microbiology comparing a stagnant lagoon to one equipped with three circulators observed no physical or chemical differences between the two: they had similar levels of BOD, nutrients, and pathogens, due to the circulators’ inability to incorporate significant oxygen into the water.

Circulation does not provide enough turbulence in the water column to disrupt thermal stratification, prevent sludge accumulation and turnover, or keep algae from taking over—all things that create objectionable odors. Circulators do have their place in lagoon-based wastewater treatment—perhaps to cost-effectively enhance the distribution of aeration provided by powered aerators, or to provide some treatment to a lagoon too remote for power infrastructure—as long as expectations for their effectiveness are kept in check.

Circulation vs. Mixing: Apples and Oranges

To be fair, circulation is not the same as mixing, and a device intended to add some movement to the water column should not be expected to provide enough energy to keep solids in suspension, transfer oxygen, and prevent sludge buildup, algae, and odors. However, lagoon circulators are often presented as having these capabilities.

Because a large part of the expense of an aerated wastewater lagoon is power consumption, solar or wind powered circulators can be attractive to budget-crunched municipalities, especially in remote locations where power infrastructure is not already in place.

However, spending tens of thousands of dollars on a low energy circulator with the hope that it will meet the treatment needs of a lagoon system may be penny wise and pound foolish. Permit violations for not meeting effluent standards and odor complaints will cost much more in the long run.

Prevent Spring Lagoon Odors

A healthy, well managed lagoon is virtually odorless from a distance, even in spring and fall turnover seasons, and should not be generating complaints from the neighbors. It has sufficient dissolved oxygen levels to allow the bacteria to break down the BOD. In addition, robust mixing through the water column prevents stratification and keeps solids in suspension, promoting aerobic conditions for expedient BOD removal. Mixing also keeps sludge at bay to maximize the lagoon’s capacity and maximize treatment time: Sludge buildup takes up valuable volume that will shorten retention times, and adequate retention time is critical to the lagoon process.

Sufficient aeration and mixing will correct or prevent virtually every cause of lagoon odor. Triplepoint’s Ares Aeration® unit provides both aeration and mixing, combining the mixing advantages of lagoon coarse bubble diffusers with the efficiency of fine bubble diffusers in a high flexibility, low maintenance, portable unit. For more information, download our Ares Aeration brochure or contact us and we will be happy to help you with your lagoon aeration project.