The alpha factor is the single most elusive, overlooked, and abused element in the design of lagoon aeration systems. It is a catch-all factor used in the Field Transfer Efficiency equation to correct for the difference between clean water ASCE testing and “dirty” water use. It corrects for aeration type, bubble size, and wastewater contaminants, allowing you to take clean water tests and predict what the real-world pounds of oxygen transferred will be—converting Standard Oxygen Transfer Efficiency to Field Transfer Efficiency.

In this article, we’ll review SOTE and explain how the alpha factor is used to adjust a lagoon aerator’s SOTE to approximate its performance in a particular application.

What is SOTE?

SOTE stands for Standard Oxygen Transfer Efficiency, the measurement of how much oxygen is transferred by a given aerator in clean water under the American Society of Civil Engineers’ testing standards. It is commonly used in aeration calculations to determine how much air is required to provide the necessary pounds of oxygen needed for aerated lagoon treatment. The higher the percentage SOTE number, the less air is needed.

SOTE stands for Standard Oxygen Transfer Efficiency, the measurement of how much oxygen is transferred by a given aerator in clean water under the American Society of Civil Engineers’ testing standards. It is commonly used in aeration calculations to determine how much air is required to provide the necessary pounds of oxygen needed for aerated lagoon treatment. The higher the percentage SOTE number, the less air is needed.

Bubble size is the single biggest factor in determining SOTE. The smaller the bubble, the higher the efficiency. This is due to the ratio of the bubble’s surface area to its volume, as well as the speed at which it rises through the water (the larger the bubble, the faster it rises). A slower-rising bubble has more time to transfer its contents to the water.

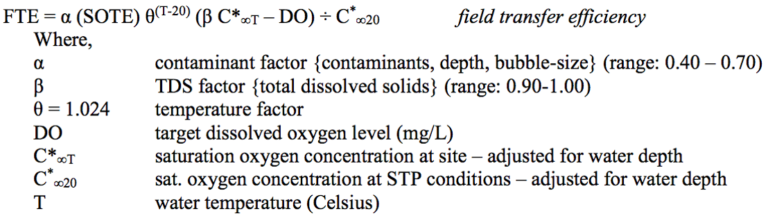

The SOTE of a particular aerator is then adjusted to field conditions using the Field Transfer Efficiency equation.

Field Transfer Efficiency

The Field Transfer Efficiency equation below takes an aerator’s lab-tested efficiency in clean water and adjusts it based on field conditions—things like ambient and water temperature and the dirtiness of the water—to provide a more realistic assessment of its likely performance in the field.

Lagoon Aeration Efficiency: The Alpha Factor

The first adjustment to SOTE in the Field Transfer Efficiency equation is the alpha or contaminant factor, represented by α. Because SOTE is based on clean water performance, that number must be derated to account for contaminants that may inhibit the transfer of oxygen from the bubble into the water.

For example, fats, oils, greases, and detergents can build up on the surface of the bubble as it rises through the water column and create a barrier that inhibits oxygen transfer. Surfactants tend to build up easily on slow-moving fine bubbles. To account for surfactant build-up in deep, fine-bubble applications, an alpha-factor of 0.4–0.5 should be used. For shallow applications, this number can be increased to as much as 0.6 or 0.65. Coarse bubbles are less affected by surfactants because of the turbulence they create and the speed at which they rise—both inhibit full surfactant coverage. For coarse bubble applications, 0.8 is commonly used, but may be increased or decreased based on depth or flow rate. Some surface aerator manufacturers claim an alpha value as high as of 1.0 to 1.2, because the propeller forces the air in almost an emulsification manner—cutting through any surfactant issues. Many independent sources use 0.75 to 0.9 for the alpha value of surface aerators.

Sometimes the alpha factor is ignored altogether or a generic number (such as 0.8) is applied to all applications. This is misleading and can result in claims of performance that can never be met. In fact, until the 1980s, aeration systems were designed with an alpha factor of 0.8, which resulted in undersized aeration systems and inadequate treatment.

Depending on the contaminants in the wastewater, the alpha factor may or may not be a dominant issue. Greases and other surfactants in the wastewater coat the surface of the air bubble, thereby reducing the effective area of oxygen transfer. In a shallow lagoon, or a coarse bubble application, this may not make much of a difference. But in a deep lagoon, where the surfactants have a lot of time to attach to the bubble, and in a fine bubble application, where the increased surface area is of primary importance, the alpha factor can have a significant effect.

Municipal vs. Industrial Wastewater

Municipal wastewater, which is fairly homogeneous and lacks heavy contaminants, generally has an alpha factor of 0.6, which means an aerator will be about 60 percent as efficient in wastewater as it is in clean water.

Industrially, high fats, oils, and grease projects will result in a much lower alpha factor, in the 0.25–0.4 range. Caustic wastewater, like from pulp and paper, is also more inhibiting to oxygen transfer and might have an alpha factor as low as 0.4. It’s important to be conservative in alpha factor assumptions while at the same time ensuring parity with similar technologies.

Testing for Alpha Values

Typical alpha values are generally close enough for most applications, but for applications that require a higher level of accuracy, alpha values can be determined with off-gas testing.

To off-gas test, a device is placed out in the pond, and a hood is placed at the surface to catch the bubbles as they rise. While it’s impossible to contain all of the bubbles, with a representative sample an engineer can analyze the oxygen concentration of the ambient air and compare it to the oxygen concentration of the off-gas bubbles. This will show how much oxygen was transferred to the water, and when air release depth and design parameters are taken into account, an accurate, site-and product-specific alpha factor can be established.

Alpha Values in Lagoons

A study published in Water Science and Technology, Alpha correction factors for static aerators and fine bubble diffusers used in municipal facultative aerated lagoons, found that efficiency improved over the lagoon treatment process.

Testing with fine bubble diffusers in mixed liquors resulted in an alpha factor that ranged from 0.68 in the first lagoon to 0.91 in the fourth, which makes sense—the aeration performance approached the clean water SOTE as the water got cleaner.

Conclusion

There is no alpha factor of any specific aerator. There is an alpha factor of a specific aerator in a specific wastewater. Every facility technically has its own independent alpha factor, but this is impossible to ascertain without testing. Triplepoint, along with everyone else, makes educated assumptions about the alpha factor given what we know about the wastewater in question (municipal vs. industrial, high FOG, high loading, etc.).

It’s important to keep the alpha factor in mind when evaluating aeration technologies to be sure that the aerator performance being represented reflects how it will actually perform in the field. Because alpha factors often aren’t clearly understood, some manufacturers fudge the number to assert a better efficiency than is possible in a real-world application.

Talk to the Lagoon Experts

At Triplepoint, we’re committed to helping lagoon operators maximize treatment while minimizing capital and operations costs. We can provide you with design calculations, preliminary layouts, and a lifecycle cost analysis to demonstrate how Ares Aeration® can cost-effectively upgrade your lagoon system to improve efficiency and meet even the most stringent limits. Talk to the lagoon experts!