Efficient Lagoon Aeration: Design Conditions

Having efficient lagoon aeration is important to any wastewater treatment lagoon because aeration typically accounts for 50–60% of energy costs. With this in mind, we have developed this article on the factors that contribute to lagoon aeration efficiency: the design conditions that affect the aeration calculations in the basis of design; the adjustments that need to be made to the design to account for factors in the field, and how to design an efficient lagoon aeration system layout.

The designer of an aeration system for wastewater treatment lagoons must take into account many different factors to achieve an optimal design. These factors vary by system, often competing against one another. For example, increasing the amount of air going through each diffuser lowers the total number of diffuser units needed and subsequent capital costs. However, this can increase the backpressure at the blower and drive up power costs. What is the optimal flow rate per diffuser? The system designer must understand the relationship between these tradeoffs, how to calculate them, and their relative importance to the wastewater lagoon system. This brief discussion will highlight each of the key factors and qualitatively describe their effect on the efficiency of a lagoon aeration system.

1. SOTE

What is SOTE? SOTE stands for Standard Oxygen Transfer Efficiency. It is the measurement of how much oxygen is transferred by a given aerator in clean water under the American Society of Civil Engineers’ testing standards. It is commonly used in aeration calculations to determine how much air is required to provide the necessary pounds/kilograms of oxygen needed for treatment. The higher the percentage SOTE number, the less air that is needed to transfer the required amount of oxygen to water.

What aeration factors determine SOTE? Bubble size is the single biggest factor in determining SOTE. The smaller the bubble, the higher the efficiency. This is due to the ratio of the bubble’s surface area to its volume, as well as the speed at which it rises through the water (the larger the bubble, the faster it rises).

SOTE has a role to play in lagoon aeration efficiency because if less air is needed to provide the necessary oxygen, then potentially a lower blower horsepower is required. This can lead to lower energy costs. However, it is important to realize that SOTE alone is not a measure of energy efficiency: backpressure together with the air requirement determines horsepower needed. For example, one fine bubble diffuser could have an SOTE of 3% per foot of depth, but have a higher operational backpressure than an alternative diffuser that is capable of 2% per foot. In that case, while the first diffuser will require less air to provide the necessary pounds of oxygen, it could require the same amount of horsepower/energy consumption as the second.

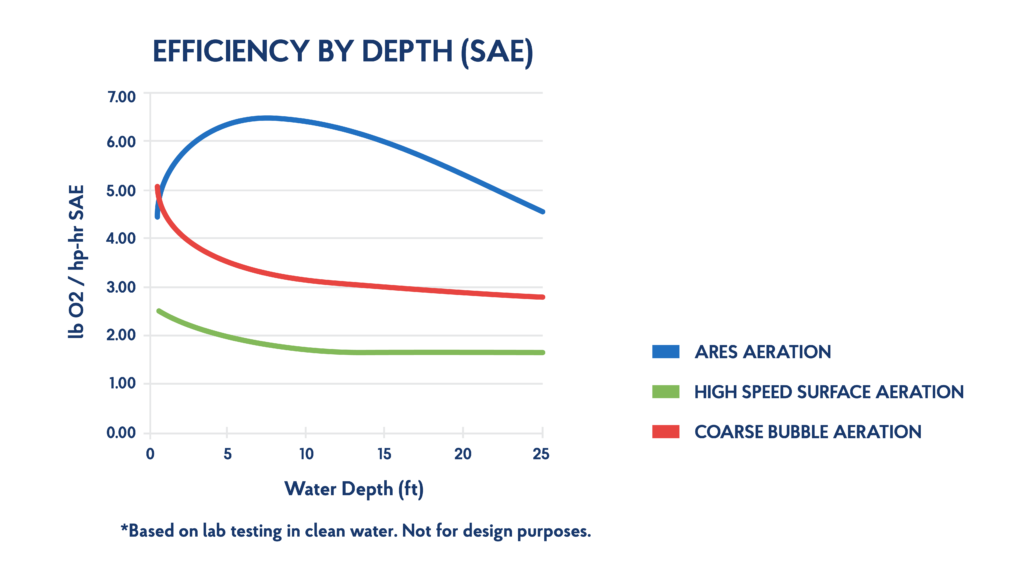

2. SAE

SAE, or Standard Aeration Efficiency, is intended to help the designer compare the operating costs of different aerators. Measured in terms of pounds of oxygen per horsepower hour, it incorporates both SOTE and blower horsepower. As a result, it is a more complete metric that allows different aerators’ energy efficiencies to be compared side by side. While SAE is rarely factored into the actual aeration calculations, it is a good metric for comparing the energy efficiency of different technologies in an “apples to apples” fashion.

Difficulties with SOTE and SAE

There are a number of difficulties in making apples-to-apples comparisons of different aerators based solely on SOTE or SAE. For starters, there are different standards and methods for testing, both within the United States (ASCE), and abroad. Secondly, many aerator manufacturers advertise high SOTEs with very little data to back them up. (We’ve seen independent test results that came in at one-third to one-half of the manufacturer’s claims). An aeration system designer should never select equipment without certified independent lab results to back up the manufacturer’s claims. Preferably, the tests should be conducted by the same lab under the same conditions.

Moreover, the purpose of aeration in a wastewater lagoon system is more than just to add the necessary oxygen to water; it is also to mix. Mixing ensures that the organic matter, bacteria and oxygen all come into contact with each other, thereby facilitating the wastewater treatment process. Without proper mixing, your lagoon could have the most energy-efficient aeration possible, but still not achieve your effluent objectives. For more information on mixing see our article on Causes and Effects of Wastewater Lagoon Sludge.

3. Fine vs. Coarse Bubble vs. Surface Aeration

Fine bubble aeration: Fine bubble diffusers generally produce bubbles of about an eighth of an inch in diameter, or less. They are usually fairly consistent and regular in size. These smaller bubbles have more contact area per volume of air, and they tend to climb the water column more slowly. This results in more oxygen transferred, more efficient lagoon aeration overall, and thus a higher SOTE and SAE. For fine bubble diffusers, the SAE can range from 4–7.0 lbs, or more, of oxygen per horsepower hour. For more information see our article on Pros & Cons of Fine Bubble Aeration.

Coarse bubble aeration: Coarse bubble diffusers produce bubbles larger than a quarter of an inch in diameter. They are usually irregular and inconsistent, sometimes producing very large bubbles of an inch or two, interspersed with smaller ones. Some coarse bubble diffusers employ various methods of mechanical separation, fixed or moving, to try to split up the larger bubbles. Generally, coarse bubbles are regarded as effective mixers; however, they are less efficient than fine bubbles at providing the necessary oxygen. For coarse bubble diffusers, the SAE tends to be about 2–3 lbs. of oxygen per horsepower hour. See our article on the Pros & Cons of Coarse Bubble Aeration for more information.

Surface aeration: Mechanical surface aerators sit on the surface of a lagoon and are designed to mix and churn the water into the air. This air/water contact promotes oxygen transfer. Surface aerators are among the least efficient of lagoon aeration alternatives due to the high horsepower and energy requirements. A typical SAE for surface aerators is approximately 1.5–2.25 lbs of oxygen per horsepower hour. Our article on the Pros & Cons of Surface Aeration has more detailed information on this lagoon aeration alternative.

Surface aeration: Mechanical surface aerators sit on the surface of a lagoon and are designed to mix and churn the water into the air. This air/water contact promotes oxygen transfer. Surface aerators are among the least efficient of lagoon aeration alternatives due to the high horsepower and energy requirements. A typical SAE for surface aerators is approximately 1.5–2.25 lbs of oxygen per horsepower hour. Our article on the Pros & Cons of Surface Aeration has more detailed information on this lagoon aeration alternative.

4. Flow Rate

The amount of air pushed through a diffuser has an effect on the efficiency at which it operates. For example, if airflow per unit is increased, aeration efficiency decreases because backpressure generally goes up and the blower needs to consume more energy to provide the required air. Contrarily, running an aerator at the low end of the design range can create very efficient SOTE; however, this will likely result in the need for more aerators. More aerators will increase capital cost for purchasing the diffusers in addition to extra piping infrastructure for delivering air. In addition, more aeration equipment leads to a higher installation labor cost and increases the long run maintenance costs.

Generally there is an optimal airflow rate for each diffuser technology; see below some examples of the different flow rates you can expect to find with wastewater lagoon aeration systems:

| type | airflow |

|---|---|

| Fine bubble aerators | 5–10 cfm |

| Coarse bubble aerators | up to 15 cfm |

| Triplepoint Ares Lagoon Aerator | 35 cfm |

Triplepoint’s Lagoon Aerator has a higher airflow capacity per unit due to its combination of both fine and coarse bubble in one portable unit.

5. Depth

For diffused aeration systems, the deeper the aerator, the more efficient it is. While not perfectly linear, many aerators provide their SOTE as a measure of depth. For example, a good coarse bubble diffuser may produce 1% of SOTE per foot of depth, while a good fine bubble diffuser may produce about 2% of SOTE per foot of depth.

There is a tradeoff between depth, energy efficiency, and capital costs. For example, if a lagoon is 15 feet vs. 10 feet deep, less air and aeration equipment is required to provide oxygen needed; however, the backpressure will be higher requiring a larger blower that will consume more energy. Contrarily, if the depth is 5 feet, then the backpressure is lower, but there is more air and aeration equipment required to diffuse that air, driving up capital costs. Generally, optimal aeration design for a fine bubble system is between 8 and 10 feet depth.

For surface aerators, this relationship is not as clear. A surface aerator in a deep lagoon of 15 feet or more will struggle to provide enough mixing than it would in a shallow lagoon of 5 feet or less. However, it will not use any more power either. Generally it is understood that surface aerators, depending on their style and horsepower, are only capable of mixing the first 5–6 feet of the water column.

In conclusion, when designing an efficient lagoon aeration system, it is important to be aware of the pitfalls and tradeoffs involved during design. SOTE does not equal energy efficiency, and, while SAE is a way to compare the relative energy efficiencies of each aeration unit, it ultimately fails to account for the importance of mixing. In addition, the interplay between depth, airflow per diffuser unit, and blower backpressure all play a role in determining blower horsepower and energy consumption. By understanding the determining factors and tradeoffs involved, you will better be able to balance them in order to design an efficient lagoon aeration system.

Efficient Lagoon Aeration: Part II Field Conditions

One of the key aspects of designing an efficient lagoon aeration system is properly taking into account the conditions in the field. Factors such as wastewater composition, barometric pressure, and ambient temperature all play a role in the end design efficiency. The truth is that there is a big difference between the efficiency of an aerator under clean water lab testing conditions and the efficiency in actual wastewater.

In this section we will be looking at the how to best design the layout, header, and piping of the aeration system for maximum lagoon aeration efficiency.

Aeration System Lab Results

Clean water oxygen testing is generally performed under standard American Society of Civil Engineers (a.k.a. ASCE) lab testing conditions. It is intended to normalize results between aeration systems and manufacturers. It is not intended to predict oxygen transfer efficiency in wastewater field conditions. To get a better feel for what the actual field conditions and results will be, adjustments must be made to the lab results. Failure to properly adjust the lab results for the field conditions during design can lead to system failure in a variety of forms, such as:

- High lagoon BOD, TSS and ammonia effluent

- Lagoon odors

- Lagoon algal blooms

- Low lagoon DO

- Undersized aeration system

- System failure

- Rapid equipment degradation

- High lagoon maintenance costs

Field Condition Adjustments

There are a variety of field conditions that you need to adjust for when choosing an aeration system for your wastewater lagoon. The most important ones are outlined below.

1. Dissolved Oxygen (DO)

DO is one of the key concepts in aeration efficiency. A wastewater lagoon with no aeration will have all of its natural dissolved oxygen consumed by Biochemical Oxygen Demand (BOD). This will result in anaerobic/anoxic lagoon conditions. At this point the wastewater lagoon will have a DO reading of 0.0 or close to it. If you were to entirely saturate the water with oxygen, the DO level would increase to a maximum of 10.71 mg/L (at sea level). However, as you approach saturation it becomes more difficult to get the oxygen to dissolve, similar to the way a wet sponge doesn’t soak up water as well as a dry one.

Many aerated wastewater lagoon designers target a DO level around 2mg/L. This strikes a nice balance between having too little oxygen (anoxic conditions) and too much, which generally results in a waste of power. The higher a designer sets the lagoon DO target, the more aeration that is needed. This is an important thing to look at when comparing different lagoon aeration alternatives, as the DO field design point tends to vary based on each manufacturer’s design preference. If you are looking to compare aeration systems on an apples-to-apples basis, make sure they’re designed with the same DO level in mind.

2. Elevation and Air Pressure

As elevation goes up, air pressure goes down, as does the amount of oxygen in the air and the saturation level of DO in the water. For example, a wastewater lagoon at 500 feet above sea level may require 2% more air than the same lagoon at sea level. At 1,000 feet it may require 7% more, and at 5,000 feet it could be up to 50%. This is another important design factor to keep in mind, especially when comparing different aeration systems side by side—for a accurate comparison, make sure that they are both designed with the same elevation.

3. Temperature and Theta Factor

As temperature rises, the equilibrium concentration level decreases substantially. Maintaining a high DO level when temperatures are low is much easier than when they are high. However, with temperature there is also an offsetting factor (theta), which is generally accepted to be 1.024. This indicates the increased transfer efficiency with increased temperature. At low DO levels, the theta factor dominates, causing an increase in efficiency with increased temperatures. At medium to high DO levels, the saturation correction factor dominates and higher temperatures lead to lower efficiencies. (I realize this might be a little more complicated. Don’t hesitate to get in touch and we can have a more in-depth discussion about this).

4. Beta Factor

The beta factor is generally assumed to be between 0.9 and 1.0. It represents an adjustment to the saturated dissolved oxygen level at the site of the wastewater lagoon, based on total suspended solids. For most wastewater lagoons, this number is assumed at approximately 0.95, however, it may vary depending on the level of TDS (Total Dissolved Solids).

5. Alpha Factor

This might be the most elusive, overlooked, and abused element in the design of wastewater lagoon aeration systems. It is a catch-all factor used in the wastewater industry to correct for the difference between clean water use in the labs, and “dirty” water use in the field. It also corrects for aeration type, bubble size, and wastewater contaminants. Designers have been known to either ignore it altogether, or apply a generic number (e.g. 0.8) to all applications. Both of these tactics are misleading and can result in lagoon aeration systems that are designed incorrectly for the given field conditions. Particularly in deep lagoons and with fine bubble applications, the alpha factor will have a significant effect. Here are a few benchmarks of the type of alpha factor that can be utilized in different lagoons and applications:

| Application | Alpha |

|---|---|

| Deep Lagoons with Fine bubble | 0.4–0.5 |

| Shallow Lagoons with Fine bubble | 0.6–0.65 |

| Coarse Bubble Diffusers | 0.8 |

| Surface Aerators | 1–1.2 or 0.75–0.9 |

The alpha factor largely depends on the composition of the wastewater you are trying to aerate. Normal municipal wastewater is understood to be fairly consistent from location to location and, therefore, alpha factors can be safely assumed. For industrial wastewater, on the other hand, it is much harder to know what alpha should be used. This is mainly because the composition of industrial wastewater is not consistent from location to location. Ultimately, the only way of knowing what the alpha factor should be for a particular type of wastewater is to actually test for it. In most cases this is not a feasible proposition; as a result, engineers tend to make educated guesses.

Be wary of manufactures that use alpha factors that fall outside of the given ranges outlined above. Utilizing a liberal alpha factor is one of the classic “smoke and mirrors” tactics for manipulating aeration calculations to get a lower power requirement for one system versus another. In the end, each proposed aeration system is going to be aerating in the same wastewater and utilizing the same basic method of creating bubbles in water; whether it’s one type of fine bubble diffuser versus another, when it comes to aeration efficiency, one fine bubble is likely to be the same as another.

Conclusion

In conclusion, in order to design an efficient lagoon aeration system one has to take into account the field conditions that ultimately determine how much energy is actually used. Factors including dissolved oxygen target, site elevation, and wastewater composition all play a critical role in making the adjustments from lab efficiency to field efficiency. By being aware of the industry best practices and standard assumptions, you will better be able to compare different aeration systems side by side knowing that each manufacturer is utilizing a common basis of design. Nonetheless, field transfer efficiency is only one factor that goes into an efficient lagoon aeration system—layout design is also critical.

Part III Layout Design

A big part of designing an efficient lagoon aeration system involves how aeration infrastructure fits into the project site. Length of header, location of power, and number and type of aerators are all examples of important considerations that can affect the efficiency of your lagoon system. In this section we dive in to what to pay attention to when designing an aeration system layout to ensure that maximum energy aeration efficiency is achieved.

Operating Pressure

For diffused air systems, power consumption and subsequently lagoon aeration efficiency is tied directly to flow rate and operating pressure.

1. Lagoon Depth: Operating pressure is largely determined by the depth of the lagoon; for example, for every 1 foot of diffuser submergence, there is 0.43 pounds per square inch (psi) of operating pressure.

In deeper lagoons, higher overall oxygen transfer efficiency can be achieved, requiring lower flow rates and fewer aerators. However, deeper lagoons also require higher operational pressure due to being deeper, thereby leading to more energy consumption. This tradeoff generally favors a deeper lagoon.

With shallow lagoons, aeration is extremely efficient per foot of depth due to the lower operating pressure; however, you need a lot of aeration diffusers and air to transfer the necessary oxygen.

2. Diffuser Type: Simply pushing air through a diffuser increases the operating pressure. The amount of operating pressure increase depends in part on the type of diffuser you use. For instance:

- Fine bubble diffusers generally have a pressure loss of about 0.5–0.75 psi

- Coarse bubble diffusers generally have a pressure loss of 0.1–0.25 psi depending on how much air you are trying to push through each diffuser.

This can moderately increase the power consumption of a lagoon fine bubble system. However, because lagoon fine bubble aeration is more efficient at transferring oxygen to water than the lagoon coarse bubble, it uses less air, resulting in less pressure drop in the air lines (or smaller, less expensive, air supply piping). This tradeoff, from an overall energy perspective, overwhelmingly favors fine bubble over lagoon coarse bubble diffusers.

3. Airflow Per Diffuser: The airflow per diffuser is correlated with operating pressure: the higher the airflow, the higher the backpressure. In the case of fine bubble diffusers, the more air you push through each, the lower the efficiency, as they will produce larger bubbles. With a lower lagoon aeration efficiency, more air is needed to provide the necessary oxygen. There is a tradeoff here because if you run diffusers at a higher airflow, you will need fewer of them, therefore lowering your capital costs. However, you will increase your backpressure, which is likely to lead to higher operating costs. Generally, from a lagoon aeration efficiency perspective, it is better to operate a diffuser at a lower airflow per unit.

4. Header & Lateral Design: Pushing air from the blower through the header and laterals to the diffusers increases operating pressure further. The amount of backpressure through a header and lateral system depends on:

- The total cubic feet of air per minute (cfm) required for aeration. Less air generally means the backpressure can be lower depending on the pipe size and length.

- Pipe inner diameter (ID) determines how much volume the air has to travel through the pipe itself.

- The length the air header pipe: The longer the pipe, the more friction the air will have as it travels through it and the higher the backpressure.

- Finally, the number of fittings and valves that the air has to travel through also adds friction and subsequent backpressure.

There are often a number of tradeoffs when designing a header system. For example, if the location of the aerated lagoon is not close to where a sufficient power source is, then you have to decide whether the cost of pumping the air a longer distance at a higher backpressure over 20 years is less expensive than installing a new electrical service closer to the lagoon. Generally, an efficient lagoon aeration system is designed so that the total backpressure between the blower and the header is a maximum of 0.5 PSI.

Mixing

When designing an efficient lagoon aeration system, mixing has to be a critical part of the equation. Ultimately, you can design an extremely efficient aeration system, but if it fails to adequately mix and keep solids in suspension, then eventually sludge will build up and lead to diffuser clogging. Our article Wastewater Lagoon Mixing Alleviates Odor & Sludge Issues is a case study of the importance of wastewater lagoon mixing. When diffusers clog and foul, invariably backpressure will increase at the blower and cause motors to consume more power making your once efficient design turn into an energy hog or fail completely. For more information on what can happen when there is inadequate mixing, see our blog Causes and Effects of Wastewater Lagoon Sludge Explained.

There are a number of factors to keep in mind when designing for effective lagoon mixing:

1. Partial Mix vs. Complete Mix: A complete mix lagoon design generally means that the aeration system is designed with 10–15 cfm per 1,000 cuft of water—for most systems this means that higher airflow is needed for mixing purposes than that needed for oxygen transfer. Most lagoons, on the other hand, tend to be partial mix, meaning that there is no set airflow requirement and fewer diffusers are needed.

2. Area of influence: In a partial mix design, it is a good idea to position aerators so that they cover the lagoon adequately enough to minimally avoid dead zones. As a rule of thumb, the maximum area of influence of each aerator should generally be touching each other. Different types of diffusers have different areas of influence. Our Ares Aerator®, for example, can have areas of influence up to 125’ in diameter around the diffuser. Purely fine bubble diffusers can have areas of influence between 20–25’ in diameter because they are unable to move as much water per assembly. This generally means that more fine bubble diffusers are needed for mixing—this drives up capital and long run maintenance costs.

Almost every decision when developing a layout design will affect how efficient your lagoon aeration system ends up being. Whether considering factors such as lagoon depth, diffuser backpressure, or header and lateral design, to name a few, understanding the tradeoffs will help you be smarter about each decision. Don’t forget, at the end of the day, lagoon mixing is the linchpin of any successful lagoon aeration system. If you spread your aeration too thin you may end up with an efficient system, but one that could prematurely fail.

Contact Triplepoint for assistance designing an efficient lagoon aeration system—we can provide you with design calculations, budgetary costs, preliminary layouts and lifecycle costs analysis.