Replacing coarse-bubble system with Triplepoint’s Aerators saves sanitary district over 40% on electricity and maintenance costs.

Energy consumption represents the highest operational cost for an aerated wastewater treatment lagoon system. Here’s how one sanitary district improved their lagoon aeration efficiency and reduced power, operations, and maintenance costs by replacing their obsolete coarse-bubble aeration system with Triplepoint’s Aeration Diffusers.

About South Suburban Sanitary District

The South Suburban Sanitary District’s (SSSD) lagoon facility serves commercial business and residences in Klamath County and parts of Klamath Falls, Oregon, just north of the California-Oregon border. Nicknamed “Oregon’s City of Sunshine,” Klamath Falls enjoys 300 days of sunshine a year, with cold snowy winters and hot summer days.

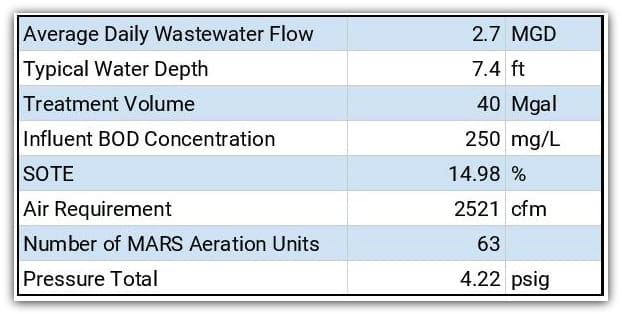

SSSD’s four-cell lagoon system processes an average of 2.7 million gallons per day of wastewater at 250 mg/L BOD5, with an aerated treatment cell outfitted with aging coarse-bubble diffusers. Although coarse bubbles effectively provide mixing to keep solids from settling as sludge, the oxygen transfer efficiency is low. (For a more detailed evaluation of coarse-bubble lagoon aeration efficiency, see our blog post: Lagoon Coarse Bubble Aeration: Pros & Cons.)

In addition to the energy demands of the coarse-bubble aerators, the equipment was falling into disrepair and requiring more frequent maintenance.

Room for Improvement

While the lagoon system was providing adequate effluent quality, SSSD’s District Manager Michael Fritschi was open to new technologies that could help to improve treatment and reduce energy consumption and costs. He turned to Energy Trust of Oregon for an energy audit and expertise. Energy Trust of Oregon is an independent, nonprofit organization focused on reducing energy costs and sustainability.

SSSD’s current system consisted of 328 coarse-bubble turbine tubes producing an actual oxygen requirement (AOR) of 6,040 lbs/day. What type of lagoon aeration system could provide the same AOR at a lower energy cost?

Triplepoint’s Aerators

SSSD chose to rehabilitate its lagoon system with Triplepoint’s Aerators, which feature unique Double Bubble Technology™, combining the mixing capabilities of coarse bubbles with the superior oxygenation of fine bubbles in a modular, portable unit:

- Coarse-Bubble Mixing: Large bubbles are released at the bottom of the static tube creating a draft effect that pulls water and liquefied organic matter up from the basin floor. This produces wastewater mixing by highly agitating the water column, thoroughly churning and circulating the entire wastewater basin.

- Fine-Bubble Aeration: Fine-bubble diffusers surround the static tube, maximizing oxygen transfer efficiency (OTE) while minimizing energy consumption. Enhanced by the mixing effect of the coarse bubbles, this combination provides the ideal environment for biological treatment.

- Optimized Energy Distribution: The aerator’s modular design allows for treatment to be evenly distributed throughout the entire wastewater lagoon, mixing and aerating from the basin floor to the surface.

The following video is a small scale demonstration of our aeration technology. The media demonstrate how robust the coarse bubble mixing is and the draft effect it creates, pulling water up from the floor and through the unit. Simultaneously, the fine bubble diffusers are releasing hundreds of thousands of small bubbles for maximum oxygen transfer.

Extensive independent testing has proven that Triplepoint’s aerator has a best-in-industry Standard Aeration Efficiency (SAE). It is is 50–60% more energy efficient than high-speed surface aerators and 40–50% more efficient than coarse-bubble diffusers.

SSSD replaced 328 coarse-bubble diffusers with 63 Triplepoint aeration units able to provide the same level of treatment with less energy. The increase in lagoon aeration efficiency reduced power demands by over 36%—saving almost 335,000 kilowatt hours of electricity per year, or enough to power 30 average homes!

SSSD saved money on installation as well: Because Triplepoint’s aerators are modular, portable, and self-weighted, they could be installed without dewatering or taking the system off line. They were simply lowered into the lagoon on top of the obsolete coarse-bubble system, which was abandoned in place.

The aerators are connected to the existing blowers via flexible weighted tubing, with no submerged moving parts to clog or malfunction. The anti-fouling design, with self-checked fine- and coarse-bubble diffusers and self-cleaning EPDM membranes, means maintenance is kept to a minimum and system downtime is avoided.

Energy Trust of Oregon offers cash incentives to encourage the use of more efficient processes, which netted SSSD $77,125 on top of their savings on electricity, maintenance, and operations. The aerators will pay for themselves in no time, and continue saving the city thousands of dollars a year for years to come.

To learn more about how Triplepoint’s lagoon aeration can improve lagoon aeration efficiency and save thousands of dollars in energy, operations, and maintenance costs, download our brochure.