Our ammonia case study of the NitrOx installation in De Soto, IA, is featured in the October 2021 issue of Treatment Plant Operator magazine! Read the story below to learn how Dan Van Langen, De Soto’s director of Public Works, teamed up with Triplepoint to cost-effectively meet the city’s low ammonia limits.

Our ammonia case study of the NitrOx installation in De Soto, IA, is featured in the October 2021 issue of Treatment Plant Operator magazine! Read the story below to learn how Dan Van Langen, De Soto’s director of Public Works, teamed up with Triplepoint to cost-effectively meet the city’s low ammonia limits.

Getting to Zero Ammonia

A new technology installed in a plant upgrade helps an Iowa town achieve 100% ammonia removal through winters even without supplemental heating of the wastewater

There’s nothing Dan Van Langen enjoys more than a day of bird hunting with his German shorthair pointer Andie.

But these days Van Langen, director of Public Works in De Soto, Iowa, is more excited talking about the bugs in his town’s wastewater lagoons than stalking pheasant in cornfields. That’s because he has finally figured out how to remove the ammonia from the effluent even in the dead of winter, when low temperatures make the bugs less active.

He found the solution with help from Triplepoint Environmental and its NitrOx® ammonia removal system. He was highly skeptical when the system was first piloted at the treatment plant in 2017, but now he is on board.

“When we consistently remove 100% of the ammonia in the dead of winter, with consecutive days of subzero temperatures, I can honestly say the NitrOx system is the best thing since sliced bread,” he says.

Tougher on Ammonia

The story began in 2011 when the Iowa Department of Natural Resources was reclassifying all rivers, creeks and streams in the state under U.S. EPA guidelines. The goal was for all waterways to be fishable and swimmable, but in many cases, ammonia levels were too high.

Iowa was not alone; the same was true across the entire Mississippi Valley. Wastewater treatment plants from Minnesota to Louisiana suddenly found themselves faced with a $900 billion unfunded federal mandate to bring ammonia levels down.

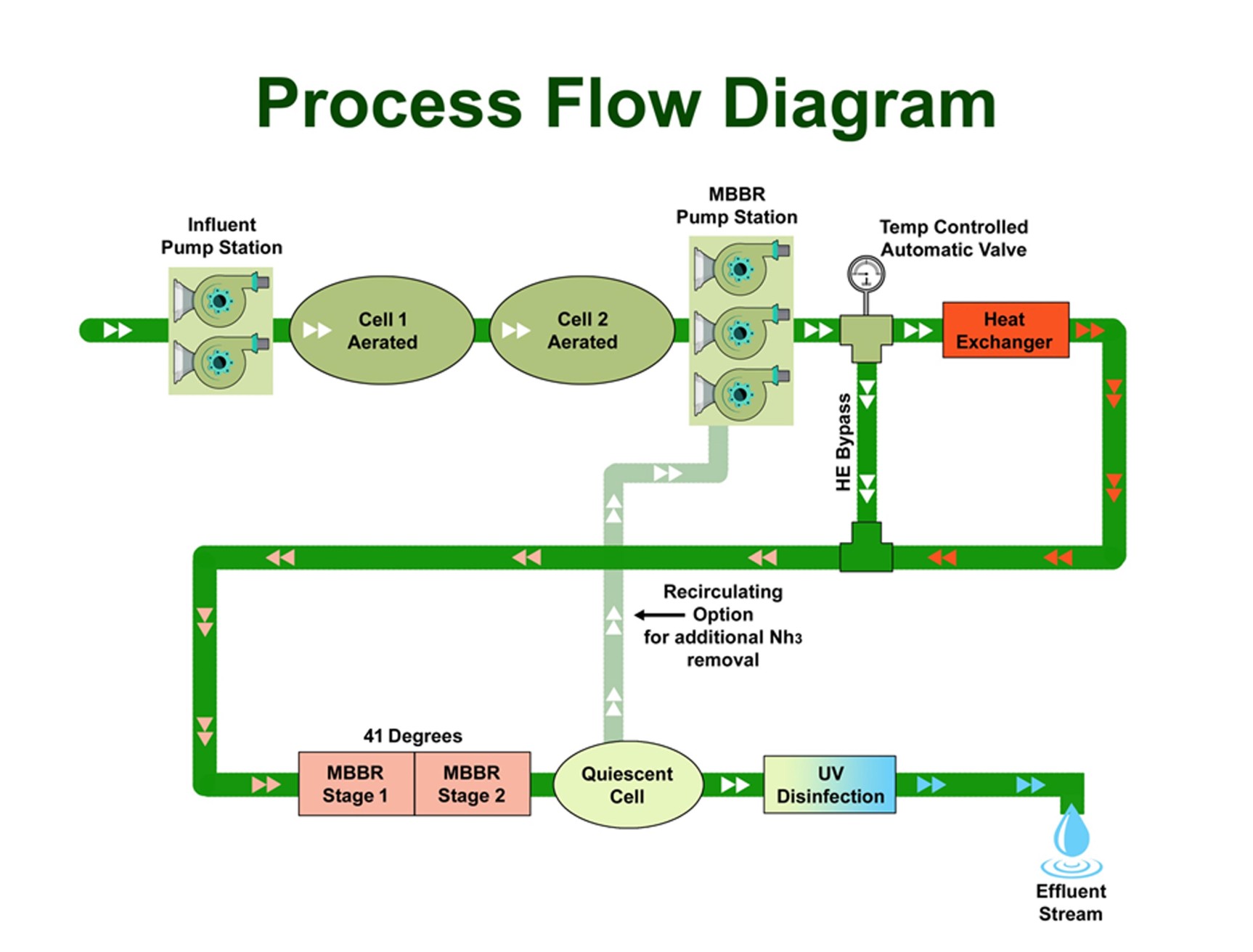

Smaller plants like De Soto’s, serving a community of about 450 households with two aerated lagoons, a quiescent cell and an average flow of 80,000 gpd, are especially challenged to make upgrades needed to satisfy the regulatory requirements.

Van Langen was more prepared than most. “I’m a stickler for having money in reserve, and we really try to budget accordingly each year,” he says. “I believe operators should plan for upgrades and be fiscally responsible. So when the state mandated us to take action on ammonia in 2016, we were financially prepared.”

De Soto’s project was part of an overall $4.2 million plant renovation that included dredging of the lagoons, replacing 62 antiquated fine-bubble diffusers with 16 of Triplepoint’s energy efficient aerators, and the ammonia system that would allow the plant to discharge safely to Bulger Creek.

Weighing Options

Before getting into the wastewater industry Van Langen was a commercial photographer who specialized in weddings. With a wife and small children at home, he jumped at the opportunity to join De Soto’s Public Works Department. Two years after joining, he was promoted to director.

Van Langen looked for an ammonia system knowing De Soto had no land to expand the plant; it is landlocked by railroad tracks to the north, a creek to the south and expensive land on the other two sides. There were also budget limitations.

He looked at a mechanical treatment facility, but the construction cost was $15 million, and the new plant would have required a Grade 3 operator at a much higher salary. The second option, an aerated rock bed nearly the size of a football field, was impractical.

The final option was the NitrOx system, a backend moving bed bioreactor with four aeration tanks 10 by 20 feet and 18 feet deep, and a small process control building for a boiler, all for $2 million. The compact size of the ammonia system and its ease of operation appealed to him.

Giving It a Try

Less appealing was that the technology was new to Iowa. And while the promised effluent ammonia numbers sounded great—an average of 0.3 mg/L even in the cold—Van Langen had his doubts.

“Mike Shoup, our engineer at the time, had met with Patrick Hill from Triplepoint and discussed doing a pilot of the NitrOx system,” Van Langen says. “Triplepoint would run the pilot at no cost to us. Given there was no risk to us, and it would show the DNR that we were taking steps to reduce our ammonia levels, I agreed to the project. But I have to admit I was the biggest naysayer of the group. Put bugs in little houses and expect them to bring our ammonia down?”

Triplepoint conducted the pilot in the winter of 2019. As it progressed, it became clear that the system would work well for De Soto and for many other wastewater plants. Van Langen had to swallow his pride when Shoup’s solution proved so successful: “After a month of zero ammonia in our effluent, I was drinking the NitrOx Kool-Aid.”

There was one caveat. Because of the need to heat the water to 41° F, thought to be the minimum temperature for the microbiology, De Soto’s monthly energy bill rose from roughly $900 to more than $4,000. “We considered it a necessary evil,” says Van Langen.

Running Cooler

Contemplating the project later that year, Van Langen had an epiphany. His ammonia permit limit for January was 3.4 mg/L, so why was it necessary to remove 100% of the ammonia? He and Triplepoint’s Patrick Hill decided to turn the temperature down to 40° F and see if they could still meet the permit.

“We knew some of some bugs would die, but so what?” Van Langen says. “Funny thing, despite the cooler temperature, the bugs kept eating. Looking at that, I said to Patrick, ‘Let’s just turn the heat off.’”

That was October 2019, and as winter set in and the water temperature in the reactors dropped as low as 32° F, ammonia removal remained at 100%.

Monthly energy bills dropped to an average of $1,485, higher than in 2018 but attributable to the new blowers, a lift station, UV disinfection, outdoor lighting and a heated building. Van Langen’s response to going heat-free with no drop in ammonia removal? “Mind blowing!”

During the winter of 2021, De Soto experienced three consecutive days of 27° below zero. While Van Langen was tempted to turn on the heat, he let his bugs work, trusting the 36° temperature of the influent to protect them. They made it through.

“Looking at the cost of the ammonia removal system, the small footprint, ease of maintenance, and the data, this is a no brainer; the best solution on the market,” Van Langen says. “A project of this scale and cost was only possible with the cooperation and understanding of our elected officials, the knowledge of our engineering department and the advice the city received from Triplepoint.”

Learn more about NitrOx

Visit our NitrOx page for detailed product information and additional ammonia case studies that demonstrate that NitrOx reliably meets low ammonia limits year round, no matter how cold it gets!