Treating wastewater lagoon BOD (Biological Oxygen Demand) is the highest priority at any wastewater facility. Without proper lagoon BOD treatment, you risk being fined by state regulatory agencies and, more importantly, jeopardizing the safety of the environment in the surrounding area. It’s your responsibility to ensure BOD is properly treated prior to discharging it into the environment.

Due to aging treatment systems, this is exactly the situation the City of Parsons, West Virginia, found themselves in during 2008. This article will examine how and why they upgraded their wastewater lagoon aeration system to better treat lagoon BOD.

Wastewater Lagoon BOD Treatment Problems

The definition of aeration according to the EPA is twofold. First, you must provide the oxygen needed to the water to give microorganisms the fuel they need to break down nutrients. Second, you must thoroughly mix the water column so that the microorganisms can come into contact with the nutrients. The more oxygen and contact created, the better the breakdown will be. For an aerobic lagoon, treating wastewater lagoon BOD effectively is dependent on aeration.

In 2008, Parsons had a typical wastewater lagoon system. They aerated with mechanical surface aerators. However, these surface aerators were consistently having maintenance problems. For a small, rural town in West Virginia, the limited financial resources meant there was only a limited budget to constantly service and repair these machines. As a result, Parsons fell out of compliance on their permit due to high wastewater lagoon BOD.

Learn more about surface aeration by reading our blog article: Pros and Cons of Surface Aeration in Wastewater Lagoons.

The nature of surface aeration systems, along with these system malfunctions, was causing a variety of problems that led to high lagoon BOD for Parsons. For instance:

- Mixing Depth—With the mechanical aerators operating from the surface, much of Parsons’ 10 ft. wastewater lagoons were left unmixed. This meant that lagoon BOD treatment was only happening in about half of the lagoon’s depth.

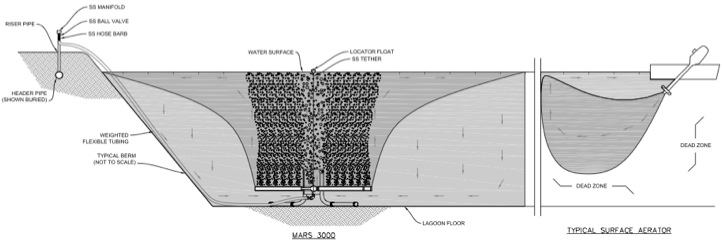

The Surface Aerators at Parsons (shown right) were effective at mixing approximately the first 6 feet of the water column. However, this left a dead zone in other areas of the lagoon where sludge accumulated untreated over time. Triplepoint’s Lagoon Aerator, on the other hand, sits on the bottom and mixes the entire water column. - Few Points of Mixing—With only a few surface aerators in the wastewater lagoon, mixing was only occurring in a few spots. Not only was the bottom half of the lagoon untouched, but all of the area between these surface aerators was also untouched. This only added to the water with untreated lagoon BOD.

Parsons was having issues maintaining their surface aerators in large part due to frequent breakdowns. Breaking Down—The 8 mechanical surface aerators on the water required constant maintenance that Parsons simply could not afford to keep up with. This only lowered the level of lagoon BOD treatment further.

- Inefficient Oxygen Transfer— Surface aerators have a much less efficient operation than other aeration systems. They yield about 1–2 lbs 02/hp-hour, whereas many diffused systems can yield 7–8 lbs 02/hp-hour. As a result, not only was Parsons paying more for their operation, they were also receiving less oxygen and less lagoon BOD treatment.

Given these points above, Parsons was not receiving either the mixing or aerating aspects of what the EPA defines as aeration. That being the case, it comes as little surprise that they were failing to treat wastewater lagoon BOD effectively enough to meet their permitted effluent levels.

Triplepoint’s Aeration System Solves Lagoon BOD Problem

In response to these struggles, Parsons sought out an alternative wastewater lagoon aeration system. They needed to address most—if not all—of the four problems listed above in order to come back into compliance.

Their search for an efficient and effective wastewater lagoon aeration system to replace their surface aerators led them to Triplepoint’s Aeration System. It combines elements of both coarse and fine bubble aerators to create a hybrid system designed to yield high oxygen levels, as well as instigate thorough, turbulent mixing. A few of the elements that attracted Parsons to the Triplepoint System were:

More Efficient Oxygen Transfer—As I mentioned before, Parsons wasn’t operating on a large budget. Not only did they need more oxygen in the water, but they also needed it at an efficient cost. The fine bubble element of the aeration system was able to increase lagoon BOD treatment in their wastewater lagoon while also decreasing their overall energy costs by approximately 60%.

- Better Mixing—The aeration sesign for the Parsons wastewater lagoon included 18 aerators. This meant that instead of just 8 points of mixing at the surface as with their old surface aerator system, they would now receive 18 individual points of mixing via the coarse bubble element. Needless to say, the total mixing coverage would be much improved compared to the surface aerator design. This mixing would now also occur from the bottom of the wastewater lagoon and move upwards. The coarse bubbles would touch all levels of the water, and thus the entire water column would be mixed. This mixing ensured that lagoon BOD treatment was occurring from the bottom to the top of the water column.

- Ease of System Maintenance—Due to the design of the system, there are fewer motors to maintain than with surface aerators. Each surface aerator has its own motor, whereas 18 Triplepoint aerators can be run via one on-shore blower. That means just one motor to maintain, and when maintenance must occur, it can occur on shore (as opposed to boating out into the water). Similarly, if maintenance is required, the wastewater lagoon does not need to be dewatered. The aerator can be pulled to the surface for routine cleaning or maintenance, and treatment of the lagoon will not suffer. As a result, Parsons’ maintenance costs decreased by 50% after installation.

With these benefits, the Parsons wastewater lagoon was able to improve both its DO levels and its mixing. Not surprisingly, their wastewater lagoon BOD levels came back into compliance very shortly after installation due to the increased lagoon BOD treatment.

Not only that, but their overall operation and maintenance costs decreased substantially. According to the City of Parsons, “The system will pay for itself within four years and save the city many thousands of dollars over its lifetime.”

Treating wastewater lagoon BOD can be a very troubling problem. A failure to treat BOD can harm surrounding water bodies, as well as cause headaches and fines for treatment facilities. Having the proper aeration system that operates cost effectively is the first step to assuring that you will be able to treat wastewater lagoon BOD for many years to come.

Learn more about how Triplepoint’s Ares Aeration® can help you improve your lagoon BOD treatment by downloading the Ares Lagoon Aeration Literature.