Six Years Ago, this Oregon Wastewater District Was Promised 40% Lower Energy Costs. Today, They’re Still Saving and Their Triplepoint Aerators Are Nearly Maintenance Free.

Sally Bratton is a native of Klamath Falls, Oregon, a rural community some 25 miles north of the California state line. She joined the South Suburban Sanitary District (SSSD) 20 years ago, one of only four women in the entire state working in the wastewater treatment industry. As the SSSD’s supervisor and lab manager, Bratton knows the business like the back of her hand.

“It’s a great career though it can be a little challenging in the winter when it snows. But, if you wait five minutes, the weather will change,” she laughs.

Six years ago, life was different at the SSSD. Like many wastewater treatment facilities in rural America, the District was facing rising energy costs and aging equipment to maintain. The 129-acre facility, with its four lagoons—one an aerated treatment lagoon—was processing an average of two million gallons of wastewater a day.

Bratton can attest to the headache of aging equipment. “The aerators in our treatment lagoon were so blasted heavy. We had a river boat like the ones used for duck hunting and fishing that we equipped with a crane to pull the aerators out of the lagoon for servicing. Three of us would be on the boat. One stood on one side of the boat with the crane while the other two stood on the other side to stabilize the boat as the aerator came up. It was a nightmare,” she says.

Seeking a solution, SSSD Manager Mike Fritschi, PE, began looking at ways to reduce expenses and maintenance issues. The District’s biggest energy hog was its 1970’s era aeration technology. The energy required to run the existing coarse-bubble equipment was the District’s largest expense. Equipment maintenance was also costly. Moving from coarse bubble to fine bubble aerators would be more efficient, but Fritschi hadn’t heard of it being used for treatment ponds.

“Lagoons need oxygen to breakdown waste in the process. As I was doing my research, I found Triplepoint and their aeration system, a hybrid that combines coarse and fine bubbles for improved oxygenation and energy efficiency. Based on projections, Triplepoint said we could reduce our energy costs by as much as 40 percent,” he recalls. “We were interested to say the least.”

On behalf of the SSSD, Fritschi approached the Energy Trust of Oregon, an independent nonprofit organization funded by the state’s utility companies to help non-profits like the SSSD as well as businesses and residents become energy efficient. The Energy Trust agreed to conduct a study and confirmed that moving to the hybrid aerators would be a huge energy and cost saver. They also awarded the SSSD $77,125 in cash incentives to replace their aerators. Says Fritschi, “The study and our Board of Directors gave us the greenlight to move forward.”

In early 2014, Triplepoint was awarded a contract to replace the SSSD’s 328 coarse bubble aeration diffusers with 63 aerators.

Triplepoint’s Tom Daugherty says Triplepoint’s aeration units are known for ease of installation. “They’re self-weighted so they can quickly be installed from the surface without having to take the lagoon offline. While it seems crazy that we were able to replace hundreds of aerators with just 63 new units, ours have very high airflow and mixing capacity and are very energy efficient. Fewer aerators also means less to maintain.”

Once in place, the difference between SSSD’s new and old aerators was obvious. Daugherty explains. “The old surface aerators throw a lot of white water into the air, which makes it look like a lot is going on, but it’s not doing anything to oxygenate the lower layers of a lagoon. It’s a waste of kinetic energy. Triplepoint’s aerators are “quieter” acting and have a best-in-industry Standard Aeration Efficiency (SAE). This makes them 40–60 percent more energy efficient than high-speed surface aerators and coarse bubble diffusers.”

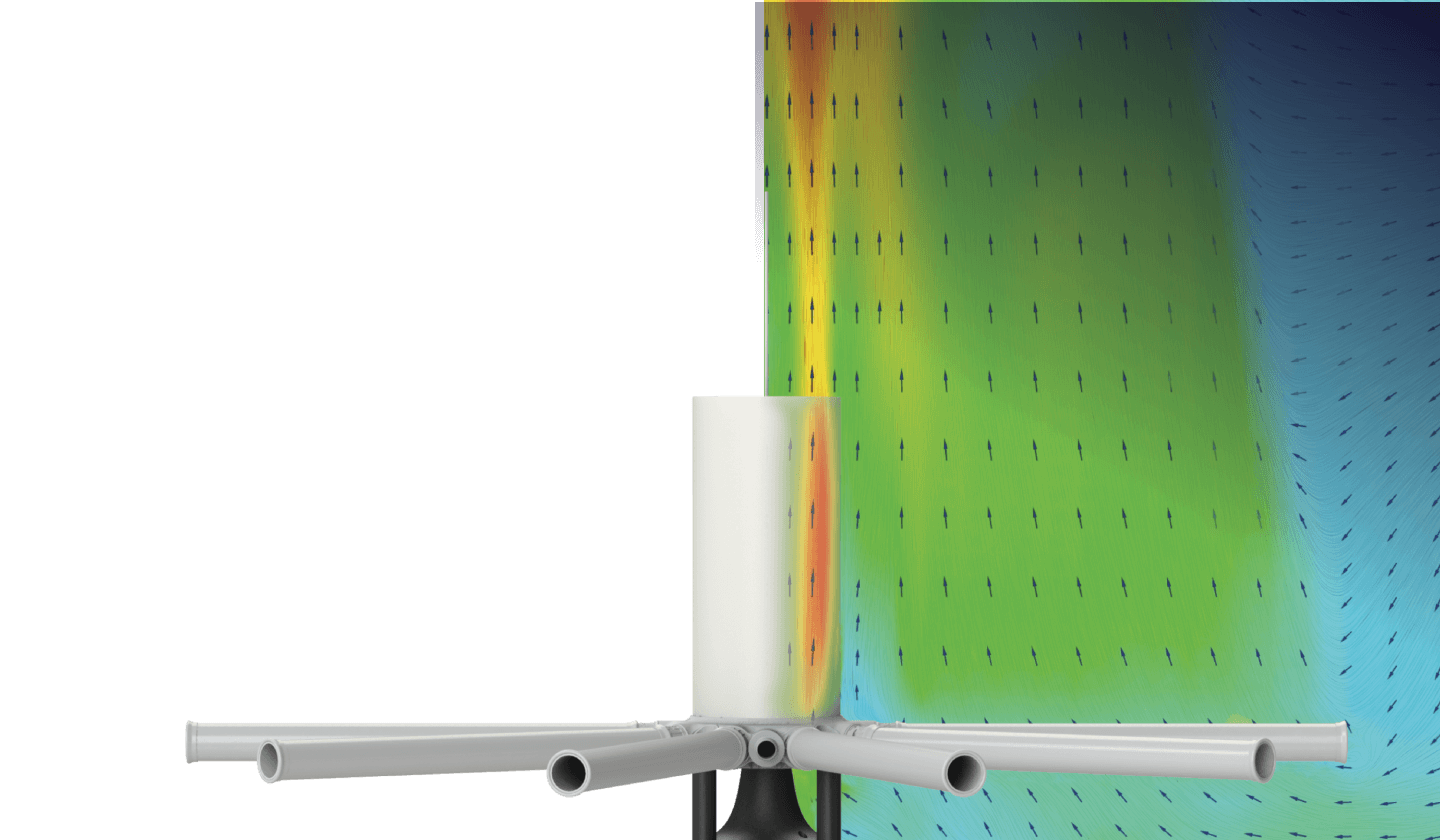

Triplepoint’s Double Bubble Technology

- Large bubbles are released at the bottom of a static tube creating a draft that pulls water and liquified matter up from the lagoon floor and through the unit. This produces a highly agitated water column that thoroughly mixes and circulates the entire lagoon.

- Fine bubble diffusers surround the static tube, maximizing oxygen transfer efficiency (OTE) while minimizing energy consumption. Enhanced by coarse bubble mixing, the fine bubble oxygenation maximizes biological treatment.

- The unit’s modular design optimizes energy distribution throughout the lagoon, from basin floor to the surface.

In two days, Sally Bratton and her team pulled up, washed, inspected, and re-submerged 63 Triplepoint aerators. Two days. This maintenance is recommended every three years. That’s it.

Fast-Forward to 2020

Day-to-day operations at the SSSD have become much easier and efficient. The rickety river boat used to maintain the old aerators is long gone, replaced with a more stable pontoon boat with plenty of deck space for a smaller crane and to pressure-wash the lighter Triplepoint aerators. Not that they need much attention. In the six years since they were originally installed, the aerators have been serviced once.

Day-to-day operations at the SSSD have become much easier and efficient. The rickety river boat used to maintain the old aerators is long gone, replaced with a more stable pontoon boat with plenty of deck space for a smaller crane and to pressure-wash the lighter Triplepoint aerators. Not that they need much attention. In the six years since they were originally installed, the aerators have been serviced once.

Says Bratton, “Scheduled maintenance is once every three years. In late summer 2018, my team was able to pull up, clean, inspect, and re-submerge all 63 aerators in two days. They are so much lighter and easier to handle. It was a total timesaver.”

From an energy and cost savings, the new system has fulfilled all of the District’s expectations.

“Before installing our Triplepoint aeration system in 2014, our power bill for aeration alone was $6,000-$10,000 a month. Today, we spend $4,000–6,000 a month, a 40% reduction. That’s an annual savings of upwards of $72,000, which is big dollars for a small community such as ours.” “Such a dramatic and sustainable reduction in energy costs has helped the SSSD stabilize rates for customers, reduce our carbon emissions and ensure the financial health of our district.”

Mike Fritsche, PE, District Manager, South Suburban Sanitary District

Another unanticipated benefit of Triplepoint low maintenance lagoon aeration system is its flexibility. Should the SSSD require additional load capacity, all the District to do is add more aerators rather than having to increase the footprint of the lagoon itself.

“Small cities and water districts are challenged to maintain rate stability when the infrastructure behind their services is expensive. Engineers like Mike Fritschi at SSSD have to be proactive and visionary—write grants, invest in more energy-efficient equipment, install solar power—because every little bit helps.”

Tom Daugherty, Western Regional Manager, Triplepoint Environmental

Building Toward a More Sustainable Future

The Triplepoint Aeration System project was just part of the SSSD’s overall energy reduction strategy. Thanks to a forward-thinking board of directors, the District recently installed a 750 kilowatt solar system to generate their own electricity. This has resulted in additional reductions to energy costs; over the next 25 years, the SSSD will save $2 million.

“Sustainability has definitely become more important to our District and our customers over the last decade. It’s really a change in perspective,” Fritschi says. “Now we look to the wastewater treatment as resource recovery. We will be recycling water for re-use. Other facilities are selling biosolids as a fertilizer. Some facilities are creating methane to use or sell. And, we’re using more energy-efficient technology.”

He adds, “In the end, it’s about our community and ratepayers who count on us to control costs, keep rates stable and now, be as sustainable as possible.”