Along with surface aerators, fine bubble aeration is one of the most often selected solutions for wastewater lagoon treatment. Installed at the bottom of the lagoon, fine bubble aerators release tiny bubbles that slowly rise to the surface of the water. These thousands of tiny bubbles collectively have a very large surface area. As a result, they can efficiently and effectively transfer oxygen to the entirety of the water column.

This article will attempt to give a full, unbiased breakdown of fine bubble aeration in wastewater lagoons. Please don’t hesitate to contact us with questions or comments. We’ll be happy to dig into more details.

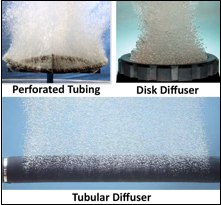

The 3 Main Types of Fine Bubble Aerators

- Membrane Disk Diffusers – Your typical membrane disk diffusers are going to be between 9″ and 11″ in diameter. They will be composed of EPDM rubber, mounted on a base plate, and will screw into a header or lateral. The EPDM will expand as air is pumped through it, which will open hundreds of small perforations. This results in the release of thousands of fine bubbles (less than 2mm in diameter).

There are three different types of fine bubble diffusers for aerated lagoons - Tube Diffusers – Most tube diffusers are made from a rigid ceramic or hollow plastic cylinder. These cylinders are long and thin, and are surrounded by EPDM rubber. The air is transferred and released in the same manner as the disks, except tube diffusers generally offer more surface area than disks, and thus can release more fine bubbles.

- Perforated Tubing – This type of diffuser, sometimes referred to as “Bubble Tubing,” is generally composed of LDPE with slits or holes punched in it. These small holes then leak air at pressurized airflow. However, this type of LDPE diffuser does not expand and contract to open these perforations in the same manner that the tube and disk diffusers do.

The Benefits of Fine Bubble Aeration (Pros)

Listed below are a variety of benefits you could realize by choosing to treat your wastewater lagoon with a fine bubble aeration system.

- Energy Efficiency – Boasting an Standard Aeration Efficiency (SAE) of 4–7 lbs O2/hr/hp-wire, very few aeration technologies can compete with the fine bubble in terms of energy efficiency. In many cases, switching from alternative lagoon aeration technologies, such as surface aeration or coarse bubble aeration, can save anywhere from 40–60% (or more) on energy costs.

The City of Parsons was able to reduce energy & maintenance costs by 60% by switching to Triplepoint’s Fine and Coarse Bubble Aeration. - Improved Dissolve Oxygen levels – Similarly, fine bubble aeration can also achieve Standard Oxygen Transfer Efficiencies (SOTE) of 1.8–2.2% per foot of submergence. Any other system on the market will have a very difficult time matching this type of oxygen transfer efficiency performance. If you’re installing a fine bubble aeration system in your wastewater lagoon, it’s safe to expect noticeable increases in dissolved oxygen (DO).

The City of Parsons, WV, had 8 surface aerators and replaced them with 2 blowers after installing Triplepoint’s Fine and Coarse Bubble Aeration. Fewer motors to maintain – In comparison to surface aerators, a fine bubble aeration system will likely have fewer motors to maintain. For example, where a typical surface aeration system may have 5–10 surface aerators, a fine bubble system will typically only have 2–3 blowers. Moreover, these motors are more easily accessible as they are onshore. This cuts down on maintenance time, materials, and hassle.

The Disadvantages of Fine Bubble Aeration (Cons)

As with any system, there are downsides that accompany the benefits. Below is a list of a few of the main disadvantages that wastewater lagoon facilities and operators encounter when utilizing fine bubble aeration systems.

- Difficult to Install – Many traditional fine bubble aeration systems are either secured to fixed laterals at the bottom of the lagoon, or hanging from floating laterals. With fixed laterals, the lagoon must be drained and desludged for the installation. You can expect this to be both costly and time consuming. With floating laterals, you’ll need to install the diffusers and laterals amphibiously—this can be a laborious and potentially hazardous process.

Clogged Perforated Tube Fine Bubble Diffuser Fouling & Clogging – Any fine bubble aeration technology is susceptible to bacterial fouling. This is the process whereby bacteria form on the surface of the diffuser and impinge upon the orifices. This causes increased back-pressure and wear on the blower, thereby increasing energy and maintenance costs. In the case of perforated tube diffusers, orifices can get clogged and cease working entirely, thereby decreasing overall oxygen transfer. This type of clogging is less of a concern for EPDM-based fine bubble diffusers.

A Fine Bubble tube diffuser being cleaned with a pressure washer. In order to maintain system performance, operators must clean and/or replace fine bubble diffusers on a scheduled basis. This generally involves cleaning the diffuser surface with either a pressure washer or scrubbing it with a brush. In the case of completely clogged perforated tube diffusers, full replacement can be necessary. Depending on whether the lateral system is submerged or floating, this can be a time consuming and costly task.

- Insufficient Mixing – The EPA defines aeration as being twofold: 1) adding oxygen to the water, and 2) mixing the water so that microorganisms can come into contact with nutrients and break them down. As we’ve mentioned, fine bubble aerators are extremely efficient when it comes to transferring oxygen. However, fine bubbles alone are not as effective when it comes to mixing. Since fine bubbles are so small, they do very little to disrupt or displace water in large volumes. As a result, the fine bubbles rise through the water rather calmly, often allowing solids to settle. Fine bubbles can also fail to create the contact between microorganisms and nutrients that is necessary for a more efficient breakdown and overall water treatment. Over time this can lead to sludge buildup. Increased amounts of sludge result in less effective treatment overall, and the costly process of removing sludge from the wastewater lagoon. Read our article, Causes & Effects of Wastewater Lagoon Sludge Explained, for more about how damaging accumulated sludge can be to treatment efficiency.

The Trend Towards Fine Bubble Aeration

Similar to other industries, wastewater treatment must advance with the times. With the current worldwide initiative to “Go Green,” and to find energy efficient, environmentally friendly solutions, fine bubble aeration fits in perfectly. There is some necessary maintenance, such as periodic cleaning, but maintenance is a part of any wastewater lagoon aeration system. Its energy efficiency and ability to improve dissolved oxygen levels tend to outweigh the negatives. For this reason, we’ve recently seen a worldwide trend of wastewater treatment facilities switching from surface aeration (and other wastewater lagoon treatment alternatives) to fine bubble aeration.

Triplepoint’s Ares Aerator® combines effective mixing with efficient fine bubble aeration. Download the brochure.